Solar panels on flexible substrates offer the potential for easier integration into built environments, as well as directly into electronic devices. Bringing supply closer to demand in this way could allow solar to meet a big chunk of energy demand, whilst also alleviating many of the land usage and grid stability concerns that come with it.

As such, flexible solar is attracting plenty of interest from both researchers and commercial players. Solar cell materials, however, tend to be quite sensitive. Designing and manufacturing devices that can withstand the stress of being folded and bent is challenging, and many of even the most promising solutions seen to date are still quite limited in their flexibility.

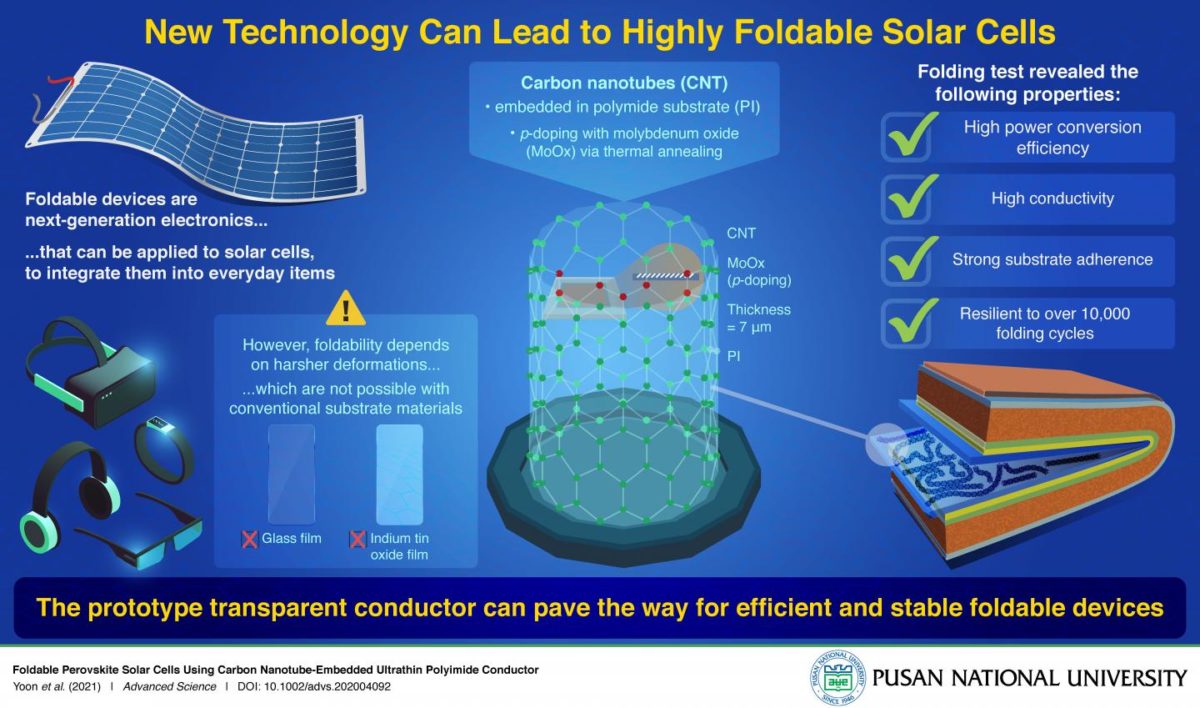

Scientists at Pusan National University in South Korea took a major step forward in solving this problem, fabricating a device that can be folded down to a ‘bending radius’ – the minimum size of fold possible without causing damage – of 0.5mm. Their device is described in the paper Foldable Perovskite Solar Cells Using Carbon Nanotube‐Embedded Ultrathin Polyimide Conductor, published in Advanced Science. Starting with a perovskite cell material and a polymer substrate, the group demonstrated a device just seven microns thick, which could withstand being folded at a 0.5mm radius more than 10,000 times.

Carbon nanotubes

Key to this performance was the use of single-wall carbon nanotubes (CNTs) as a transparent electrode layer. The CNTs were integrated into a polyimide substrate, which addressed expected problems with CNTs sticking to the substrate as the force was applied. This device was then doped with molybdenum oxide to increase its conductivity. A control device fabricated with a standard ITO electrode and polymer substrate showed severe performance degradation after 1,000 folds at a considerably larger bend radius, and could not withstand even one bend at 0.5mm.

The device achieved an impressive 15.2% efficiency, which the group claims is the highest ever achieved for any cell utilizing carbon nanotubes. Though the devices were producing at a small scale using spin-coating techniques, and the group has not investigated possibilities for larger volume processing here, the approach presents solutions to some of the issues that have held back CNT’s development for solar applications, and could greatly increase the possibilities for flexible PV in future.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.