Scientists led by the U.S. National Renewable Energy Laboratory (NREL) laid out the rationale behind a new set of specifications, titled Guidelines for qualifying PV modules components and materials for operation at high temperatures, or IEC 63126: 2020 ED1, published last year by global standards body the International Electrotechnical Commission (IEC).

The group at NREL noted that current standards regarding temperature rely on broad assumptions that may not take into account the range of temperatures, and extended periods operating at an elevated, that a module could experience in the field – particularly for hotter regions with a hotter climate such as India or Saudi Arabia, whose capital Riyadh the group took as a model to demonstrate their approach to temperature in PV module testing

98th percentile

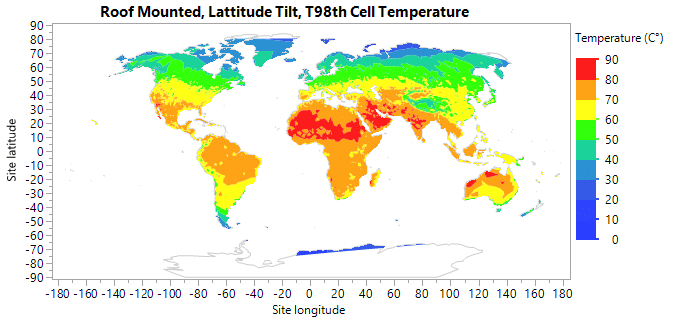

The new IEC specification outlines a different approach to testing, which should allow for better understanding of different installation environments to be worked into PV module testing earlier on. “The 2016 versions of IEC 61215 and IEC 61730 contain references to ‘rack-mount’ versus ‘roof mounting’ installations, which only indirectly reflect the actual concern which is the microenvironment of the module,” they explain. “The microenvironment is a function of both the geographic location and the means by which the module is mounted. The committee writing a high temperature module standard, IEC 63126, decided to define the module microclimate temperature by its 98th percentile temperature because this was found to be a robust, representative, and easily measured value.”

Where other approaches have focused on the maximum temperature a module operates at, the group at NREL found that dropping this down to the 98th percentile was more representative. “…there is only a very small amount of time, measured in hours per year, where the temperature is within a few degrees of this maximum.”

At the 98th percentile, meanwhile, NREL calculated that modules would operate for at least 175 hours per year, with several days where the module runs at this temperature continuously for three hours or more. They verified their approach by modeling various system types based on the climate in Riyadh, Saudi Arabia. Full details of this modeling are found in the paper Standards development for modules in high-temperature microenvironments, published in Progress in Photovoltaics.

Testing levels

While previous module testing standards often assumed a maximum module operating temperature of 90 degrees Celsius, the new standards split this into two levels – 90 and 110 degrees, and allow system designers to determine the most relevant level for a particular setting. The NREL group found that an even higher level might theoretically be needed, for example for modules insulated at the rear and installed in a high-temperature region, but was unable to find actual examples of installations like this. “There is a general belief that heat transfer restrictive installation methods would not be favored in such locations due to performance loss,” they explain. “As such, the project team holds open the possibility for higher Level, but they are considered unnecessary at this time.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.