Even as perovskite solar cell edge closer to large-scale commercial production, developing reliable processes for their large-scale processing remains a challenge. Understanding how different processes affect the film formation and structure will be an important in ensuring devices can meet expectations for quality and long-term performance in the field.

Observing these structures on a small enough scale, however, presents another challenge. And the process of synthesizing different materials and then characterizing them afterwards can be time consuming and provide limited insight. A new process developed at Lawrence Berkeley National Laboratory in the U.S. allows for real-time observation of the processing and formation of the thin film, and can also allow scientists to observe its reaction to light throughout processing.

“When people make solar thin films, they typically have a dedicated synthesis lab and need to go to another lab to characterize it,” said Carolin Sutter-Fella, a scientist at Berkeley Lab’s molecular foundry. “With our development, you can fully synthesize and characterize a material at the same time, at the same place.”

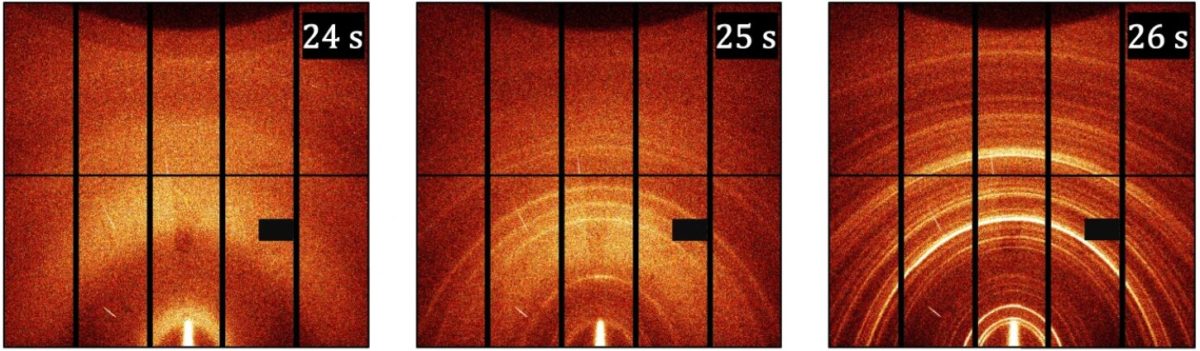

At Berkeley Lab’s Advanced Light Source facility, the group equipped an x-ray station with a laser, allowing them to simultaneously observe changes in the structure as it is formed into a thin film, and how its reaction to light develops during the process. The work is described in full in the paper Out-of-equilibrium processes in crystallization of organic-inorganic perovskites during spin coating, published in nature communications.

Popular content

They used the set up to observe methylammonium lead iodide, one of the most commonly investigated perovskite materials, during spin coating, and gained detailed insights into four stages of film formation, including the first few seconds where the precursor begins to solidify.

Quality control

The group says that its work will help other researchers to better understand their processes, and that it could eventually be used in industrial environments for quality control and real time process monitoring. “The instrument will allow researchers to document how small things that are usually taken for granted can have a big impact on material quality and performance,” said Shambhavi Pratap, lead author of the research and now a researcher with the Technical University of Munich.

They will now focus on further developing the observation tools into a set up that others can make use of. “”We know that the research community is interested in using this new capability at the ALS,” said Sutter-Fella. “Now we want to make it user friendly so that more people can take advantage of this endstation.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.