Perovskites are one of the most promising technologies for future high efficiency solar cell concepts, now being investigated by most of the leading cell and module makers. Environmental concerns over the use of water soluble lead in the perovskite materials, however, are one of a few roadblocks holding the technology back from wider commercial adoption.

Though there is plenty of research underway into lead-free perovskite solar cells, these are a way behind in terms of efficiency. And though the amounts of lead contained in a perovskite cell are small, and should remain within the module to be collected at its end-of-life, concerns over possible leakage of lead in an already water soluble form have been enough for researchers to take a closer look at managing the risks.

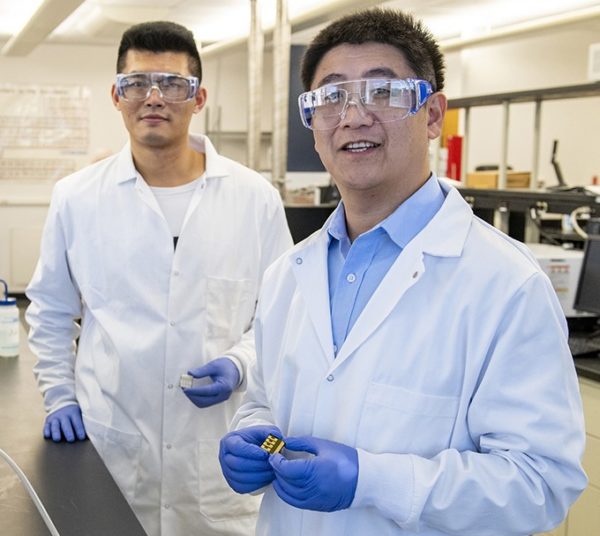

Scientists at Northern Illinois University (NIU), working alongside the U.S. National Renewable Energy Laboratory NREL), have developed a type of transparent sticky tape, which they say can be applied to a perovskite solar cell, and will absorb any lead that is leaked from it. “Our practical approach mitigates the potential lead-leakage to a level safer than the standard for drinking water,” said NIU Chemistry Professor Tao Xu. “We can easily apply our lead-absorbing materials to off-the-shelf films currently used to encapsulate silicon-based solar cells at the end of their production, so existing fabrication processes for PSCs would not be disrupted.”

Image: Northern Illinois University

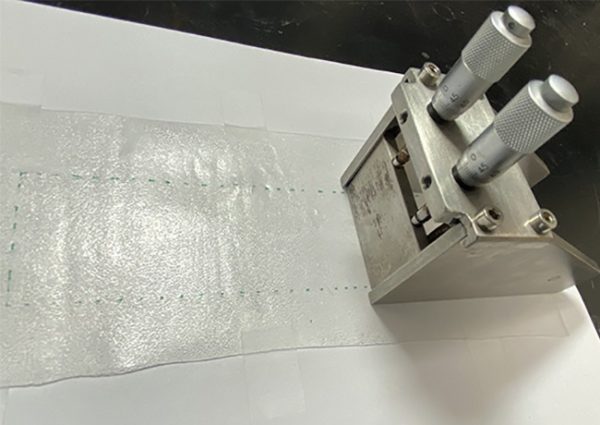

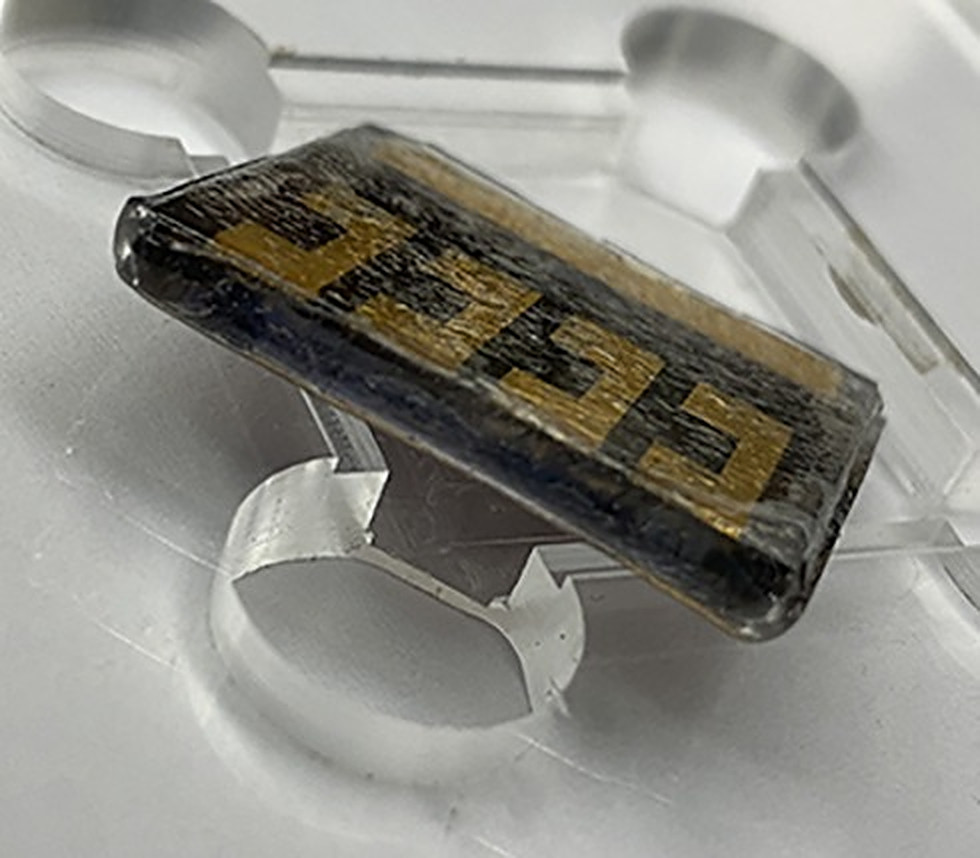

The tape solution is described in full in the paper On-device lead-absorbing tapes for sustainable perovskite solar cells, published in nature sustainability. The lead absorbing material is coated onto a film of ethylene vinyl acetate (commonly used to encapsulate various solar cell types) and then evaporated under ambient conditions, and laminated between the glass and electrode layers.

The lead absorbing layer is 5.7 microns thick on the front side and 10 microns thick at the rear, which the group estimates would allow it to absorb almost seven times the amount of lead contained in the entire solar cell. To test this, the group fabricated cells with the encapsulant. These were installed on a rooftop for three months, before being severely damaged with hammers and razor blades, and then submerged in water for seven days. The film was shown to absorb 99.9% of lead leaked from the device, keeping the amount of lead in the water safely below the guidelines for drinking water set by the U.S. Environmental Protection Agency.

Image: Xun Li/Northern Illinois University

“This work offers a convenient and industry-ready method to diminish the potential lead leakage from Pb2+ containing perovskites,” the group concluded, “facilitating future commercialization of perovskite-based PV technology.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.