Researchers at Adelaide’s Flinders University have developed a 2.8V organic polymer rechargeable battery. While the polymers used in the battery are not yet biodegradable, the team will soon switch to natural polymers like that found in seaweed – an application other Flinders researchers are examining.

The use of polymers in the battery is paramount, though hardly obvious. Plastic (a synthetic polymer) is typically used to insulate and stop electrical currents conducting, so it hardly seems a battery material frontrunner, especially for an electrode.

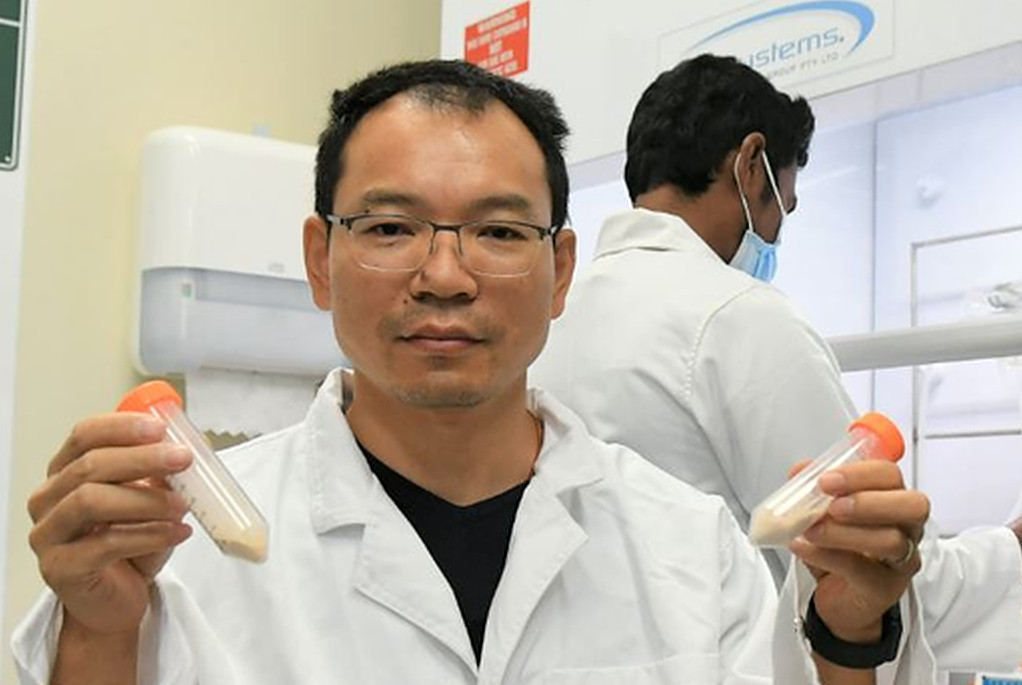

How Zhongfan Jia, a senior lecturer in chemistry at Flinders University’s Institute for Nanoscale Science and Technology, and his team have been able to use polymers is by chemically modifying them at a molecular level, something which they do in two different processes to allow both the storage and cycling of energy. (More on this modification process below.)

Currently, the Flinders polymer battery has an energy density just under 100mAh/g (milliampere-hours per gram), though the team is now working on the next generation and hopes they can double that capacity. If the polymer battery could reach 200mAh/g, Dr Jia says it would bring it in line with the capacity of lithium batteries sold just a few years ago. “That will compete,” Jia told pv magazine Australia.

What motivates the intercontinental researchers is the potential for biodegradable polymer batteries to solve the waste issue of batteries and global reliance on mined, rare materials. Moreover, the batteries could have novel high-tech applications as they are flexible and non-toxic, making them suitable for fields like biotech and beyond. “That’s something we only talk about at scientific conferences, not too much to the general public,” Jia said.

“We do know that we cannot completely replace the li-ion battery,” Dr Jia said, pointing to superiority of lithium-ion batteries voltage. “We don’t want to replace the Tesla car battery… but in our daily lives there are so many small batteries in use that are discarded.” Alongside novel high-tech applications, this is where Jia sees the most potential for the batteries, including in things like electric toothbrushes and other rechargeable appliances. Currently, his team has 100 to 200 cycles on its battery, though the plan is to reach 1,000.

Polymers and biodegradability

Most polymers used today are synthetic and come from petroleum, but they can also occur naturally in things like seaweed. Dr Gia and his collaborators’ plan is to use “materials directly from nature” in future iterations of the battery. “Next stage is we are trying to make the polymer that can degrade if you discard [the battery] in the environment only from sunshine, water and oxygen… within six months to a year.”

How it would be possible for these natural materials to store and cycle electricity is through, as mentioned, modification. The kind of battery the team has built is called a radical battery, because it uses a stable radical molecule called a TEMPO radical. A small molecule, this TEMPO radical needs to be attached to something, or else it “cannot make a certain shape, they don’t have mechanic force,” Jia said.

Which is where polymers come in. “Polymers can make your chairs, desk, boat, any shape of material that you can make. That’s the beauty of the material,” Jia stated. “We are now making this radical on the polymer… because the polymer has the property you can use [to make the battery].”

This is the first polymer modification. The second comes in the battery’s electrode, which Jia describes as “judiciously” designed. “We are now trying to store the energy in polymer,” the researcher said. “To achieve that is really difficult,” he added, noting that polymers are not conductive.

To make it conduct, the polymer has to be mixed with carbon materials on a molecular level. “Only when you do that can you use all your materials to store energy. Otherwise, if there’s some aggregation, if the polymers aggregate together, then only the surface can store energy,” Jia said. “We try to modify the polymer not only with the TEMPO radical to store the energy, but we also modify that polymer with other function and that function can stick on the carbon materials.”

Jia has been working with polymers for over 20 years, but only started researching their use in batteries around six years ago – a period which saw a marked increase in interest in this area. Jia’s team in Adelaide has been working in collaboration with Kai Zhang from the Zhejiang Sci-Tech University in China, who was a PhD student of Jia’s in Australia. The team also collaborates with researchers in Japan, Texas, at the University of Queensland and the Australian National University (ANU).

In terms of commercialization, Jia said that is still a way off. The materials needed to make the TEMPO radical are cheap, acetone and ammonium, but creating the radical does require a few steps, Jia explained. “It’s not as expensive as you think, it’s pretty cheap. But of course, when you make this into a real material to use for the battery, there are some stages [for it] to be optimized and I think that’s probably something we need to consider in the following years.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Article is unclear: Did they design a new type of battery? If so, where is the diagram for how it would work? Or did they just design a polymer material that could be used in existing batteries?