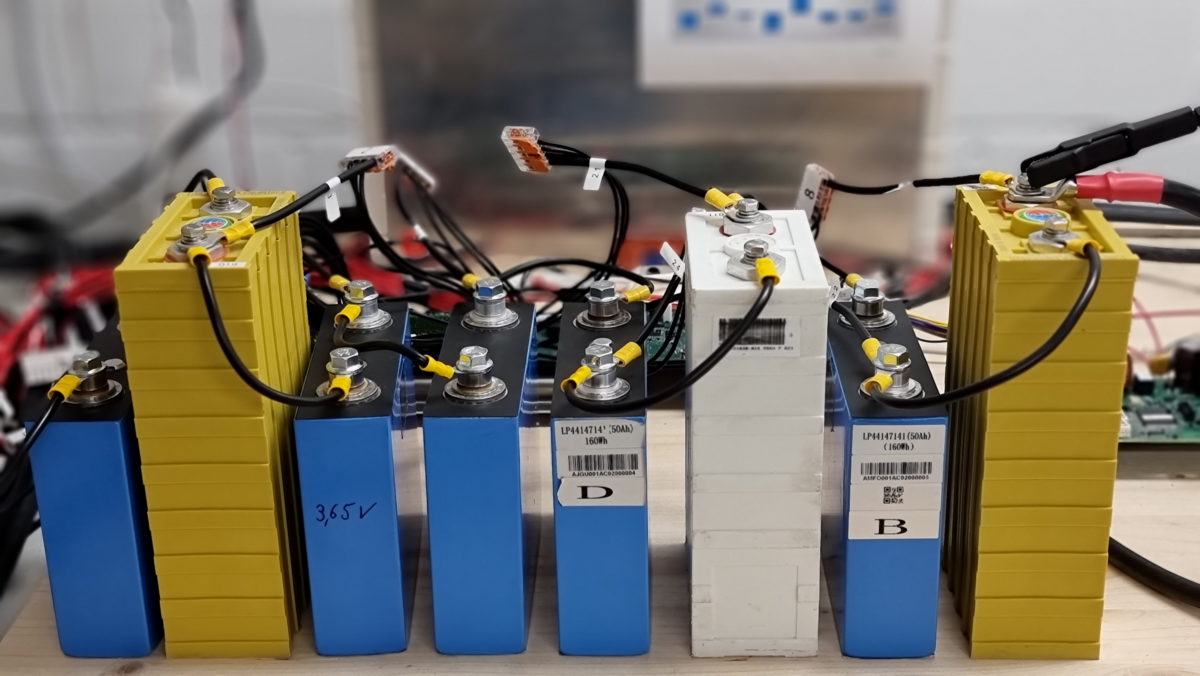

Connecting and operating very different cells as desired in second-life applications referred to as patchwork batteries could soon become a viable option thanks to a novel technology developed by Germany-based Benning CMS Technology. By virtue of its patented algorithm embedded in the charging process called ETA-Leveling, battery cells from different manufacturers, of different ages and at different nominal capacity can be connected and operated in a series. During charging, the algorithm treats each cell as if it were part of a single-cell battery application, thanks to efficiency leveling. Through targeted correction of the conversion efficiency, all cells connected in series are levelled so that they all have a uniform overall efficiency and thus achieve the end-of-charge voltage at the same time. “Up until recently, we ourselves would’ve never thought that combining cells randomly would work. It has not been possible with any of the traditional BMS [battery management systems],” says Frederik Fuchs, managing director of Benning CMS Technology. “Manufacturer, age, nominal capacity, cell chemistry – it really doesn’t matter. Our leveling process also recognizes which cells are a reasonably sensible match based on their capacities. We then combine these cells to a long-lasting battery block that works perfectly.” The company confirms for pv magazine that patchwork batteries with different cell chemistries have been limited to the demonstration phase, whereas in all other cases the systems work seamlessly with same chemistry cells from different manufacturers, of different ages and at different nominal capacity. As such, the technology could potentially unlock massive opportunities for reusing discarded battery modules that tend to end up on landfills due to prematurely aged cells. Whereas these weakest cells determine the capacity of the entire block, most of the cells in the discarded block are still in excellent condition or at least too good to recycle them. According to the company, ETA-Leveling can also be used as a BMS in the first place to prevent the premature ageing of cells as well as in defective blocks, where it can best re-level the cells so that the block can continue to be used. Already available for licensing, ETA-Leveling is suitable for battery blocks of all kinds – including all EV and stationary storage applications — and it requires no hardware changes.

In the UK, the EV charging network is in for a major boost. This week, energy company bp announced new plans to invest £1 billion ($1.3 billion) in the rollout of ultra-fast charging stations across the country, and thus approximately triple the number of public charging points in its network. The investment will be made over the next 10 years helping to meet the fast-growing demand for EV charging in the country. It will allow bp to deliver 300kW and 150kW ultra-fast charging points that are able to provide EV drivers up to 100 miles of range in around 10 minutes of charging, depending on the model of electric vehicle, and to launch new home charging products and services.

For successful decarbonization of road transport, a full variety of charging locations is crucial. In what has been dubbed the UK’s most ambitious workplace EV charging rollout, charging infrastructure provider EO Charging and energy service provider eEnergy plan to install at least 50,000 charge points for EVs at schools, colleges and universities by 2030. The first 200 installations will be completed this month and at least 2,000 chargers will be installed within the first 12 months. The latest figures from the Department for Transport show that while there are now more than 250,000 home charging devices in the UK, only 2,038 devices have been installed through the government’s on-street charging scheme since it was established in 2017, meaning those without off-street parking are being left behind. The latest announcements align with the British government's plan unveiled last week to install 300,000 charge points by 2030 on the back of a £1.6 billion ($2.1 billion) investment.

Popular content

Meanwhile, in Germany, Volkswagen is weeks away from finalizing plans for a €2 billion ($2.2 billion) EV factory where it hopes to bring notable innovations in range, charging speed and digitization. The new manufacturing facility for the Trinity electric model is to be built close to the main plant in Wolfsburg. Production of the Trinity electric model from 2026 on will be net carbon-neutral and will set new standards in autonomous driving, electrification and the digitization of mobility, according to Volkswagen. “Our goal is clear: we want to set the standard with our production,” Volkswagen brand production chief Christian Vollmer told Reuters in an interview. “If we can get to 10 hours, we have achieved something big.” By means of comparison, Tesla says it can already build a Model Y at its new Giga Berlin factory in 10 hours, while the German carmaker currently needs three times as long for its ID.3 electric car. As the electric overhaul of the German automotive industry picks up pace, the arrival of Tesla has created an even bigger sense of urgency and Volkswagen Chief Executive Herbert Diess has warned Germans must speed up to avoid getting beaten on their own turf.

Some 50 kilometers from the Acrtic Circle in Sweden, British luxury automaker Rolls-Royce Motor Cars has got a step closer to launching its first all-electric vehicle, Spectre, after completing winter testing in temperatures as low as -40℃. The carmaker has shared that the Spectre has now covered 25% of the planned 2.5 million test kilometers, simulating 400 years of use on the new EV. Its first all-electric vehicle will be by far the most technologically advanced and connected Rolls-Royce ever, and will align with the prophecy of an all-electric future of one the company's founders, Charles Rolls. “The electric car is perfectly noiseless and clean. There is no smell or vibration. They should become very useful when fixed charging stations can be arranged,” Rolls said back in 1900.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

12 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.