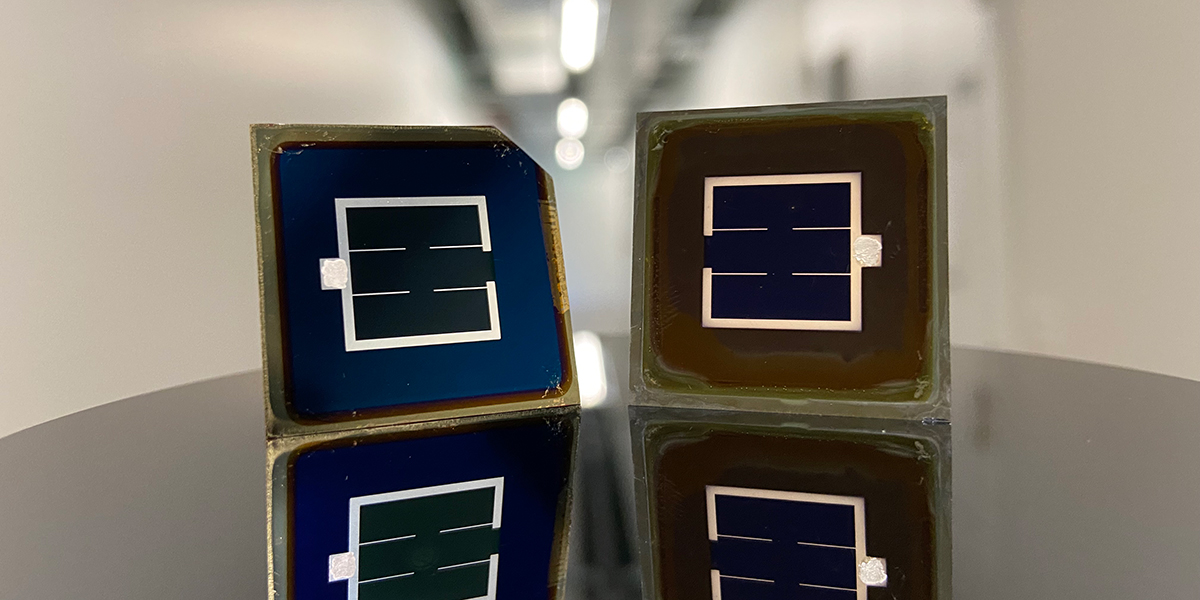

Perovskite solar cells, and tandem devices combining them with silicon, have received plenty of buzz in recent years, thanks to their potential for low-cost, high efficiency solar energy. However, achieving high efficiency and overcoming challenges related to long-term stability is only part of the picture.

Scientists and startups have presented a range of different ways for perovskite solar cells to be manufactured at scale, and we’ll probably see quite a few different approaches introduced over the next few years. Flash testing involves products that are tested under simulated sunlight to determine their efficiency, along with other characteristics.

This stage in production is important for quality control and monitoring throughout a cell or module’s lifetime, and requires a clear comparable standard for all devices. However, applying standards developed for silicon PV to perovskites raises a number of challenges. These challenges are neatly described in a new white paper by German flash-testing equipment supplier Wavelabs. Along with others, it has been hard at work on solutions for the past several years.

“PST cells require a flexible, spectrally and temporally variable light source,” said Britta Mette, a product and service engineer at Wavelabs.

The paper explains that the manufacturer sees three main challenges to flash testing of perovskite-silicon tandem devices (PSTs). First is the need for “pre-conditioning.” Unlike silicon cells, perovskites take a few seconds to stabilize when exposed to light, so they need to be exposed for longer periods to be accurate. As a solution to this, Wavelabs suggests that some form of “light-soaking” will be needed before the actual test measurement is taken, with a timing and intensity that can be varied.

“Light soaking needs to become an integral part of cell testing capabilities,” the company said. “The light-soaking technology needs to provide the option to adjust soaking times fast, easy and in a stable manner.”

Popular content

The ability to measure the two (or more) cell layers separately, while they are laid out as one device, is also a key challenge.

“PST cell flasher and testing systems need the flexibility to create varying spectra and light intensities according to the respective cell’s optimum – and to do this at ease and with precision,” the manufacturer stated. “This also includes being able to monitor the current mismatch between sub-cells during degradation tests to ensure the best match and optimal performance in the field.”

Finally, the paper notes that two-sided flash testing is needed for bifacial products. The ability to adjust light conditions to reflect various conditions, particularly for the light reaching the rear side of the cells, will be an increasingly valuable attribute for flashing equipment.

The company is naturally keen to note that its point of view that it sees its LED-based solutions as uniquely able to meet all of these challenges. It said that they allow for easy switching of different light conditions, intensities and durations, although other flashing technologies do exist on the market and are also preparing solutions for perovskites.

“Cell flashers for the characterization of PST cells must offer the possibility to take into account the specifics of different cell designs as well as to implement measurement on an industrial scale, “said Wavelabs COO and CTO Patrick Mergell. “Currently, only LED-based cell flasher technology meets the necessary measurement requirements of PST solar cells in a form that is simple, accurate and efficient.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.