The integration of lithium metal into lithium-ion batteries, in order to replace the graphite commonly used today as an anode material, will be a major step forward in energy storage technology that could allow for a big jump in battery capacity and performance. But lithium metal is a difficult material to work with, and its tendency to form “dendrite” structures that branch out of the anode and cause short circuits has limited development.

Researchers are pursuing various strategies to overcome the challenge posed by lithium metal, and a group led by Gwangju Institute of Science and Technology and Jeonbuk National University in South Korea has proposed an approach that appears to offer several advantages. The group has worked with carbon fiber paper as a replacement for the copper foil commonly used to form the lithium metal anode structure.

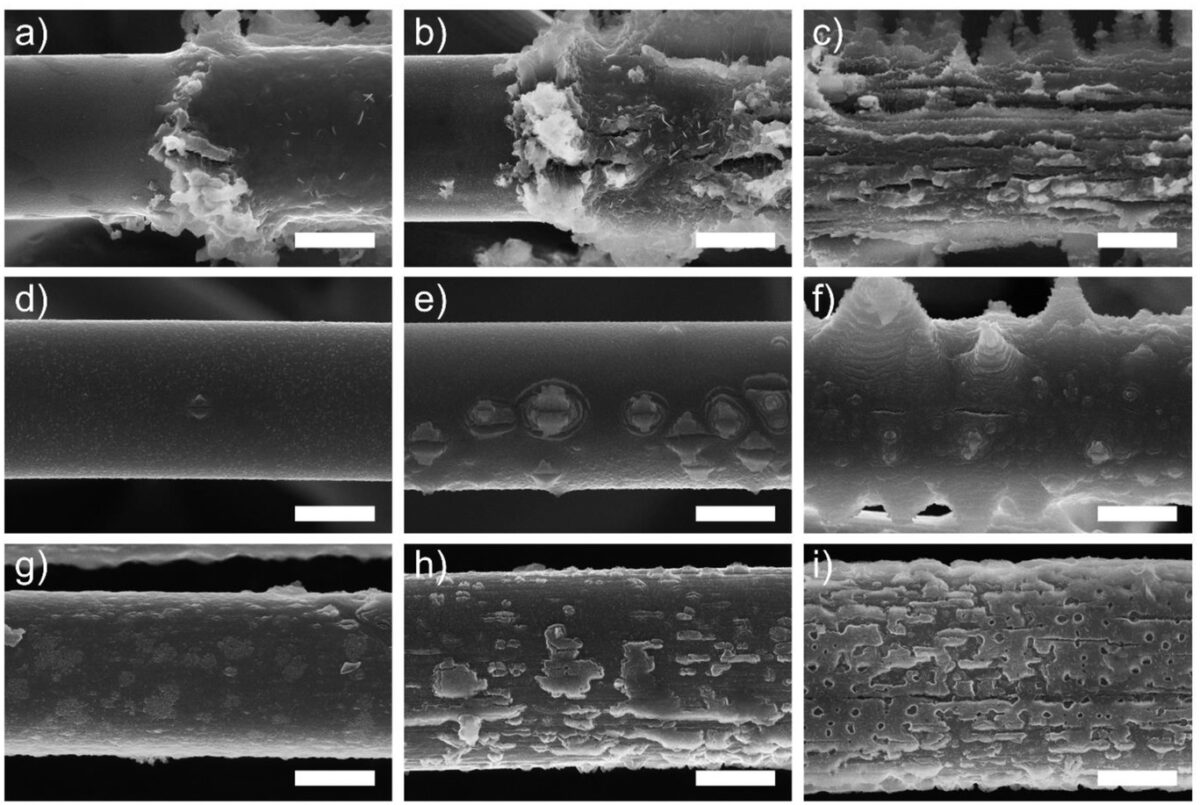

The group prepared carbon fiber with polymer binders and used a 3D framework into which lithium metal was infused. The preparation is described in full in the paper Construction of Hierarchical Surface on Carbon Fiber Paper for Lithium Metal Batteries with Superior Stability, recently published in Advanced Energy Materials.

Batteries developed using the carbon fiber/lithium metal anode achieved a high specific energy of 428 Wh/kg.

Popular content

“Considering the five times lower density and lower cost of carbon fiber compared to copper, our proposed anode material is an important achievement that can accelerate the commercialization of durable and lightweight lithium metal batteries,” said Sung-Ho Lee, head of the Carbon Composite Research Center at the Korea Institute of Science and Technology.

pv magazine print edition

The current issue of pv magazine focuses on the solar manufacturing technology enabling the new era of market expansion and high efficiency modules, including interdigitated back contact (IBC) and perovskite tandem solar cells. The magazine charts the latest technical and investment decisions in the high efficiency solar manufacturing segment and the materials and R&D underpinning them. Reports come in from France, Japan, India, Indonesia, Israel, England, the US, and China and we also examine the troubles of the solar-powered car pioneers.

Further testing showed that during cycling, lithium coated the carbon fiber without formation of dendrites thanks to the formation of an inorganic solid electrolyte interphase layer. Full battery cells fabricated using the anodes maintained 85% of their initial capacity after 300 cycles. The group says it plans to continue working on this approach, which could offer a simplified solution to integrating lithium-metal into energy storage.

“We believe that our advanced strategy, which is different to previously reported technologies, such as adding novel and toxic additives in electrolytes and surface morphology modification using complicated methods, will enable the realization of a highly stable LMA with outstanding electrochemical performance for application in the practical energy storage fields to replace conventional LiBs,” the group concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.