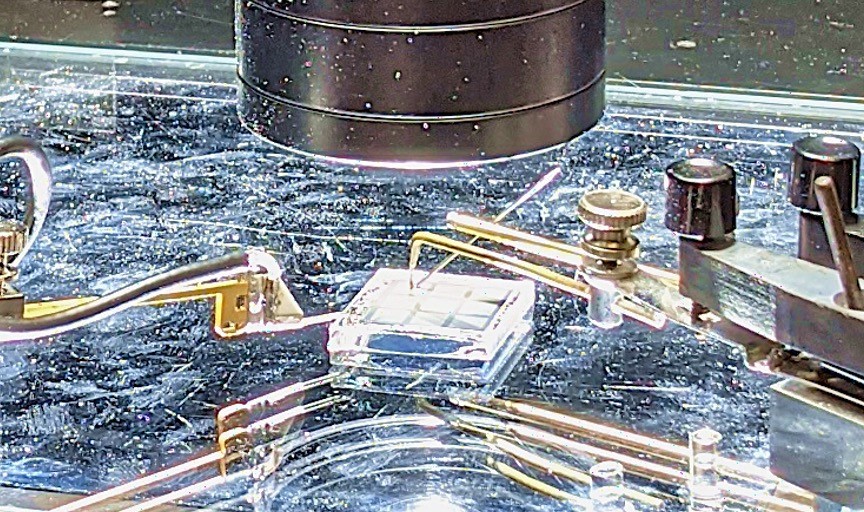

NREL and US-based thin-film PV manufacturer First Solar have built a cadmium telluride (CdTe) bifacial solar cell based on a rear interface buffer made of copper, gallium and monoxide (CuGaOx ). The scientists claim to have achieved a higher bifacial power density than any polycrystalline absorber currently manufactured at scale. They used cracked film lithography (CFL)-patterned metal grids to integrate the CuGaOx rear interface buffer in the solar cell.

“Common passivating layers, such as Al2O3 and other oxides, are highly resistive, need to be applied directly to the CdTe surface, and require a high-temperature CdCl2 treatment after they are deposited,” they said, noting that they used CFL to overcome this issue. “CFL is a low-cost method to pattern metal microgrids that have ideal properties for high resistance applications like CdTe.”

Researcher Chris Muzzillo said CFL is particularly suitable for CdTe cells due to its low cost. “We found that relative to photolithography, CFL has lower materials and equipment cost for patterning metal grids in III-V photovoltaics,” he told pv magazine.

Muzzillo and his team described their findings in “Cracked Film Lithography with CuGaOx Buffers for Bifacial CdTe Photovoltaics,” which was recently published in Nano-Micro Small. In all CFL processes, metal is grown directly on the semiconductor surface, resulting in high-quality interfaces with low contact resistance and improved durability.

In the proposed cell configuration, the CuGaOx/CFL grid samples’ showed superior passivation to their reduced gold (Au) coverage area, which in turn resulted in a higher open-circuit voltage for the solar cell. They also helped improve the device's fill factor from 70.8% to 73.3%.

Popular content

“We estimate that the previous CdTe bifacial record, with 1 sun front and rear efficiencies of 12.5% and 7.6%, respectively, generates 16.3 mW cm−2 at 1 sun front + 0.5 sun rear,” the research group said. “On the other hand, our best CFL grid produces 20.3 mW cm−2 at 1 sun front + 0.5 sun rear—a 25% jump in record bifacial CdTe power density, and at 1 sun front + 0.1 sun rear, our cell has 39% higher power density.”

Muzzilo said that commercialization of the cell is up for consideration.

“Compared to bifacial silicon, the rear efficiency of bifacial CdTe remains relatively low,” he concluded. “We will continue to work on boosting front and rear efficiency, with a goal of demonstrating high enough added power density to justify the added process complexity of CFL-patterned bifacial CdTe.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.