Hyme Energy, a spinoff of Denmark's Seaborg Technologies, is partnering with Semco Maritime to build a molten salt thermal energy storage demonstrator at the Gjesing Varmeværk heating plant, which is owned by regional utility Din Forsyning, in the Danish port of Esbjerg.

“The MOSS demonstration plant is the first energy storage plant ever built with molten hydroxide salts. It will consist in a 1.6 MWh storage unit, which will lay the groundwork for future facilities in the GWh range,” Ask Emil Løvschall-Jensen, CEO of Hyme Energy, told pv magazine.

He said the purpose of the plant is to display and test the company's molten hydroxide storage technology in a practical setting.

“The plant will be tested to prove our component integration, validate our system design, gain insights into the most optimal materials and components, and demonstrate operation and system control,” he said.

Therefore, the demonstration plant will only be used to produce heat. However, it is not part of the project's scope to provide heat to the district heating system in Esbjerg, the company explained.

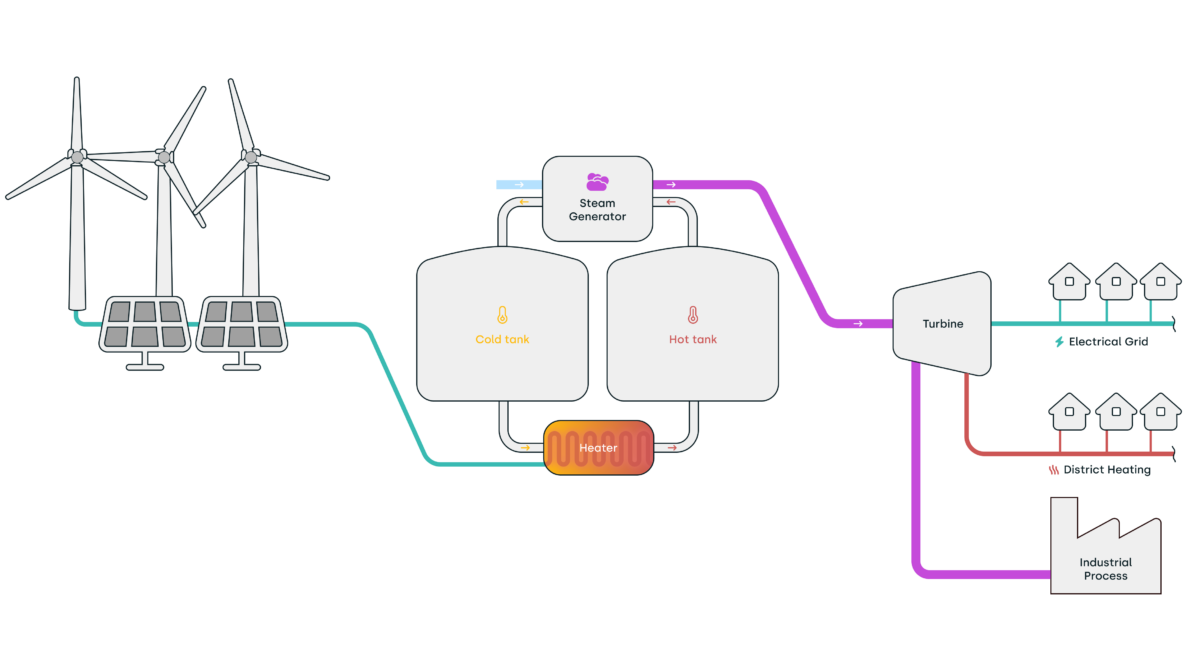

Hyme’s energy storage technology stores electricity from renewable sources in 700 C molten hydroxide salt for up to two weeks. It is based on a two-tank storage design developed for concentrated solar power (CSP) plants and Hyme’s proprietary hydroxide salt corrosion control technology.

When charging electricity from renewables is converted into heat through electrical heaters. Salt from the cold tank is circulated through the heaters and heated up from 350 C to 700 C, then stored in the hot tank.

At the time of discharge, salt from the hot tank circulates to the steam generator, where the energy is transferred to water, generating high-temperature steam. Steam can be used directly in an industrial process or used to power a turbine and produce electricity and district heating. After that, the cooled salt is pumped back into the cold tank until the next charging cycle.

The efficiency of the storage system varies according to its use. For industrial heat, Hyme envisages efficiencies of around 90%, while for co-generation, the figure is somewhere between 80% and 90 %. For power generation alone, the company expects an efficiency of around 40%.

Hyme’s storage technology is scalable and a 1 GWh facility with sodium hydroxides should be able to produce power and heat for around 100,000 households for 10 hours of discharge, said the company.

Since sodium hydroxide can be produced at low cost from seawater as a byproduct of chlorine production, the company calculates that this is six times cheaper than standard salts used for storage.

Hyme, established in 2021, is working on another demonstrator on the Danish island of Bornholm. The company's 10-15 MWh molten salt storage facility will be part of a scalable hybrid storage system which will also feature a flywheel storage system provided by QuinteQ Energy and recycled lithium-ion batteries supplied by PLS Energy Systems.

The Bornholm project dubbed 2LiPP aims to provide insights on possible repurposing pathways for combined heat and power (CHP) plants. It will provide heat, power, and ancillary services to the local network.

In November 2022, the Danish company signed a cooperation agreement with Power Engineering Consulting Joint Stock Company 2 (PECC2) to develop and build at least 2 GWh by 2030 and at least 6 GWh by 2035 of thermal energy storage projects in Vietnam.

For the MOSS Project, the engineering is expected to be completed in the second quarter of 2023, with the subsequent installation phase ending in the fourth quarter. Hyme has received backing from the Danish Energy Agency to build the pilot plant.

“The storage system at Esbjerg will be connected to the regular grid, and not directly connected to renewable sources. When charging excess electricity (when the price is low) to the storage system, the electricity will mostly come from renewable sources,” said Løvschall-Jense.

This is possible given that the Esbjerg area is well-known as a favorable geographical site for wind power, with large offshore projects already in operation.

“We have matured the MOSS project in the past year and are soon ready to kick off the construction phase with Semco Maritime,” concluded the CEO.

In addition to the MOSS Project contract, the partners have agreed to explore opportunities to collaborate on Hyme’s future larger projects, where its long-duration thermal energy storage solution will enable utilities and industries to decarbonize heat and power generation.

*This article was amended to include the roundtrip efficiency numbers.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

What is the efficiency from this sort of storage? For example, how much electricity do you get out vs what was put in?

The best storage medium is hydrogen. With the cost to produce dropping significantly it will become competitive with natural gas and gasoline. And hydrogen can be used for everything that fossil fuels and electricity can do up to industrial level.