Researchers from the Central Metallurgical Research and Development Institute (CMRDI) in Egypt have fabricate an inverted perovskite solar cell with a new type of hole transport layer (HTM) based on silver thiocyanate (AgSCN). The scientists aim to replace commonly used hole transport materials like PEDOT:PSS and copper thiocyanate (CuSCN) with AgSCN.

“CuSCN's advantages lie in the fact that it can serve as both a hole transport layer and a source of Cu doping, while AgSCN, with its greater resistivity, may serve just as a source of Ag doping with a slower diffusion rate,” the scientists explained, noting that AsSCN is also better at transferring charges between HTL and perovskite layer compared to PEDOT:PSS.

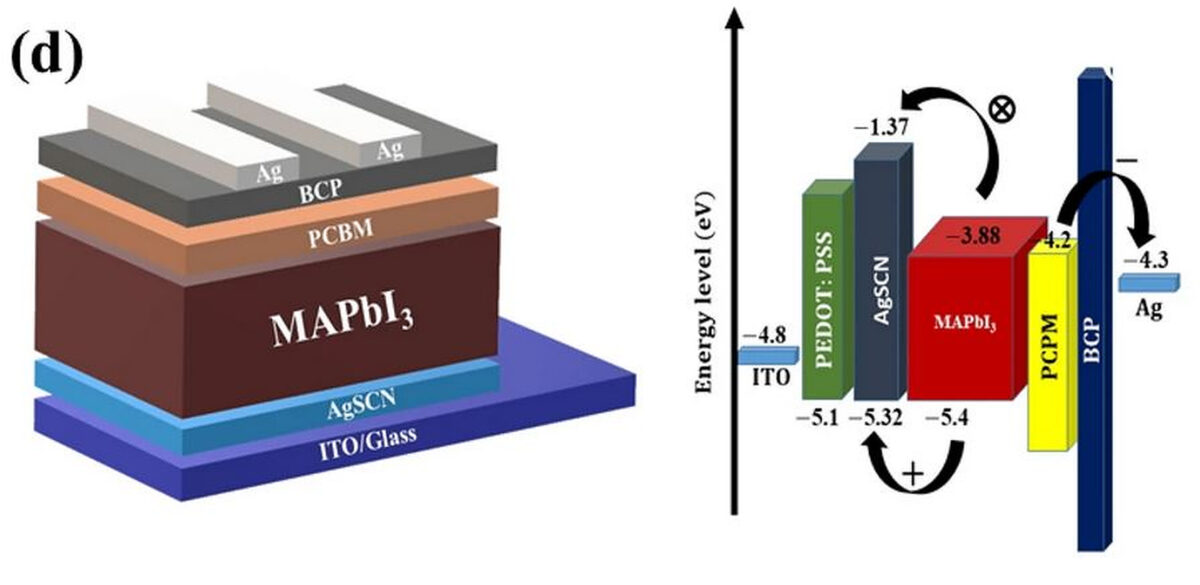

The group built the cell with an indium tin oxide (ITO) substrate, an electron transport layer (ETL) based on AgSCN, an absorber based on a type of lead-halide perovskite known as methylammonium lead iodide (MAPbI3), a phenyl-C61-butyric acid methyl ester (PCBM) layer, a bathocuproine (BCP) buffer layer, and a silver (Ag) metal contact.

The academics deposited the AgSCN thin film in a dry glove box with relative humidity between 25% and 30% at least 30 minutes before the deposition of the perovskite layer started. They then deposited the perovskite layer on the active layer on the HTL via spin coating at 4,000 rpm for 30 seconds. The performance of the solar cell was compared to a reference device constructed with an HTM relying on PEDOT:PSS.

The AgSCN-based device achieved a power conversion efficiency of 16.66%, an open-circuit voltage of 1.14 mV, a short-circuit current of 19.0 mA/cm2, and a fill factor of 77.1%. The PEDOT:PSS cell reached an efficiency of 15.11%, an open-circuit voltage of 1.04 V, a short-circuit current of 18.17 mA/cm2, and a fill factor of 80.37%.

Popular content

“The successfully achieved thin film of AgSCN made a better perovskite film with free pinholes and large grains, while the thin film of PEDOT:PSS made a similar quality perovskite film with pinholes discovered,” the group explained, noting that the AgSCN cell was also able to retain 80.9% of its initial efficiency after 500 hours in an atmosphere with 48% relative humidity.

“This low-temperature, low-cost AgSCN production method is seen as easy and scalable, which bodes well for commercializing perovskite-based flexible devices and photovoltaic technologies,” the researchers concluded. “In sum, AgSCN is a non-toxic, inexpensive rival that is simple to work with at low temperatures. It is a strong contender for creating tandem devices and high-efficiency p-i-n junction solar cells made of perovskites.”

They described the cell tech in “AgSCN as a new hole transporting material for inverted perovskite solar cells,” which was recently published in Scientific Reports.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.