A German-Chinese research group has designed a new heat-driven thermoacoustic heat pump (TAHP) system for residential heating that is claimed to offer a complementary solution to the existing heating methods.

“Our system can be used for applications such as waste heat recovery, solar cooling, and air conditioning in developing regions,” the research's corresponding author, Jingyuan Zu, told pv magazine.

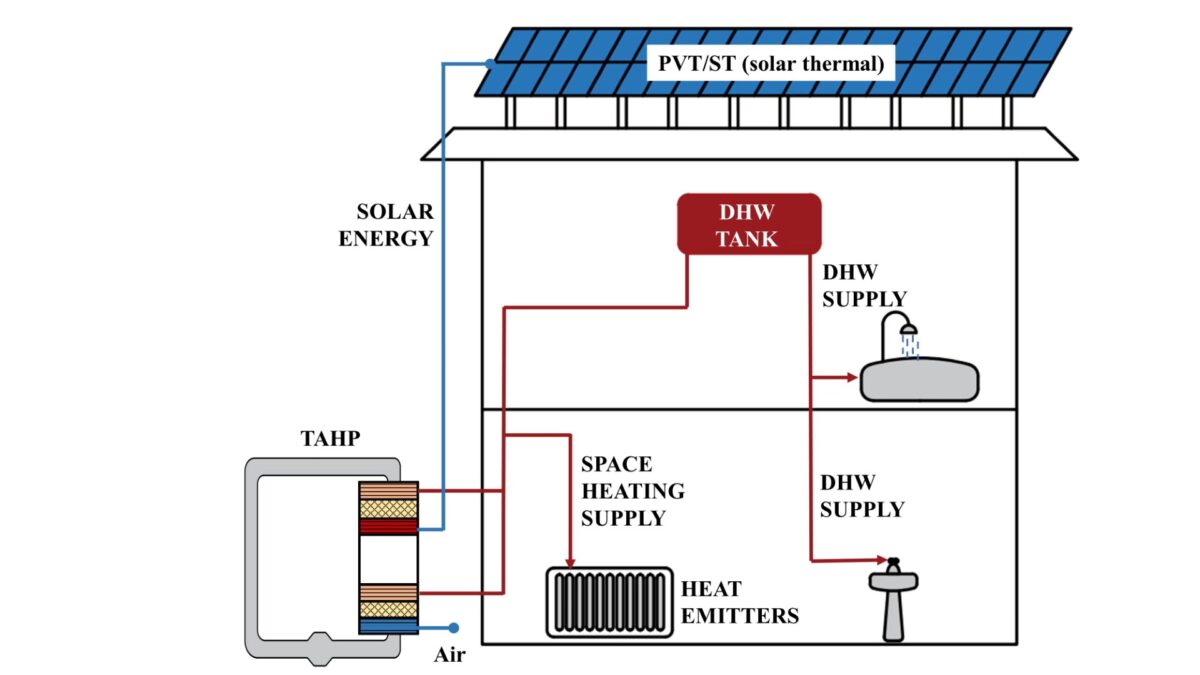

The new system uses medium/low-grade heat sources such as solar, geothermal energy, and waste heat. “This feature is particularly advantageous for remote areas where electricity is not readily available,” the scientists emphasized. “Additionally, TAHP systems are characterized by their versatility in heat source utilization and high energy efficiency.”

The researchers stressed that, currently, TAHPs are still far from reaching commercial viability, although their “simple construction” indicates that their costs may be competitive. The novelty of their work consists of designing a single-unit direct-coupling thermoacoustic heat pump system, which they said is a TAHP typology that is intended to minimize complexities and performance issues.

The proposed TAHP design includes a single direct-coupling energy-conversion core unit and a phase-shifter unit, with the core being an engine stage and a heat pump stage. “The engine stage includes a heat-sink heat exchanger (SHXe), a regenerator (REGe), a heating heat exchanger (HHXe), and a thermal buffer tube (TBTe),” the group explained. “The heat pump stage consists of a cooler, which includes a heat-sink temperature heat exchanger (SHXh), a regenerator (REGh), a heat-source heat exchanger (HSHXh), and a thermal buffer tube (TBTh).”

The phase-shifter unit relies on two resonators (RT1 and RT2) and a cavity (CT), and it is used to achieve suitable acoustic matching.

Popular content

The heat pump activates the self-excited thermoacoustic oscillation when the axial temperature gradient across the regenerator reaches a certain critical value. It then uses acoustic power to drive the heat pump stage, which transfers heat from the heat source to the heat sink. The HHXe is then heated by the medium/low-grade heat source, while the HSHXh is cooled by the air. Meanwhile, the SHXs maintains the desired indoor heating temperature via the circulating water.

The scientists tested the proposed system configuration through a series of numerical simulations using the Sage software, which they said is able to solve the conservation equations of mass, momentum, and energy in the gas domain. They then validated the results of the simulations by building a two-stage thermoacoustic heat pump system prototype.

A series of tests shows that the prototype is able to achieve, in typical heating conditions, a heating capacity of 5.7 kW and a coefficient of performance of 1.4, with a heating temperature of 300 C and a heat-sink temperature of 55 C.

“The introduced TAHP system demonstrates satisfactory heating performance under conventional heat pump operating conditions, capable of delivering an output heating capacity ranging from 3 kW to 7 kW, with a COP ranging from 1.28 to 1.42, when the heat-source temperature is 7 C and the heat-sink temperature falls within the range of 50 C to 70 C,” the researchers explained. “When considering both the energy and environmental savings, a total cost reduction of €1,629/year can be achieved.”

The heat pump concept is presented in the paper “Thermoacoustic Heat Pump Utilizing Medium/Low-Grade Heat Sources for Domestic Building Heating,” published in Energy and Built Environment. The research team is formed by academics from the Karlsruhe Institute of Technology (KIT) in Germany and the University of Chinese Academy of Science.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I think the statement “heating temperature of 300 C and a heat-sink temperature of 55 C” should have 7 C instead of 300 C