Teknisolar has been chosen to become a partner of the PEPPERONI project, a four-year research and innovation project co-funded under Horizon Europe and jointly coordinated by Helmholtz-Zentrum Berlin and Qcells. The project aims to support Europe in reaching its renewable energy target of climate neutrality by 2050, and it will also help advance perovskite/silicon tandem photovoltaic (PV) technology’s journey toward market introduction and mass manufacturing.

In its role in the PEPPERONI project, Teknisolar will design a pilot lamination line through a series of in-house tests on perovskite solar panels to later improve upon the design through implementation on the pilot line. Teknisolar’s ultimate goal is to extend the lamination technology from pilot line to gigawatt scale (mass production). PEPPERONI comprises 17 partners from 12 countries, combining European knowledge and expertise from fundamental research to small-scale testing and development of solar cells, all the way to high-throughput industrial manufacturing of large solar modules.

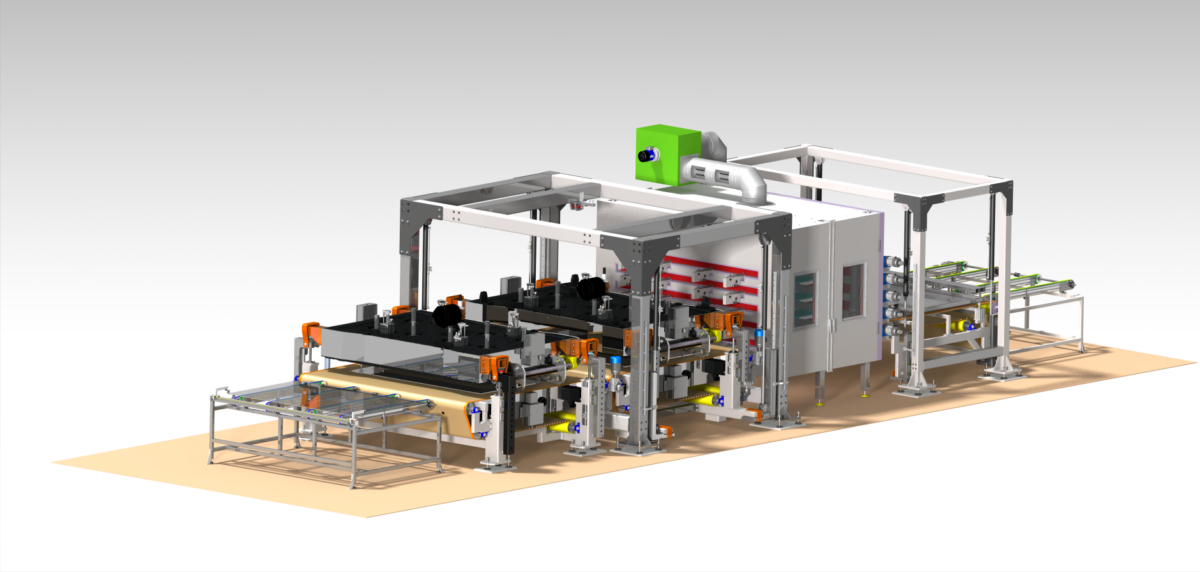

After 13 years of research and development, Teknisolar, born from an idea of Vittore De Leonibus, has developed the laminator with the fastest cycle time in the world, able to solve the problems that traditional laminators cause on photovoltaic modules. For example, laminators currently on the market are equipped with a membrane that exerts pressure on the panel, which is heated only from below. Traditional laminating technology requires rigid protection around the panel (e.g., frames or angles) to counteract excessive bending of the outer edges of the top glass due to the pressure exerted by the membrane. This phenomenon is referred to as edge pinch. If it is not prevented, this edge pinch could lead to glass breakage and over time, could be the cause of so-called “delamination,” as the panel will tend to resume its initial configuration.

Teknisolar’s “Robostak” technology does not use a diaphragm or release sheet, and the rigid press applies controlled mechanical pressure without use of a diaphragm or release sheet. The super-fast vacuum system features double-sided heating, and there is no chance of the edge pinch that is experienced with traditional laminators.

More from our partners

Another element that differentiates Teknisolar from other laminator manufacturers is the cycle-time, which is 2 minutes for G2F (Glass to Backsheet) and 3 minutes for G2G (Glass to Glass) modules. The cycle time for competitors is 6-10 minutes. This equates to a productivity increase of more than 300%.

Teknisolar recently participated at Intersolar 2023, where the company showed its customers its flexible and totally customizable solutions for the lamination of solar panels.

The company reports that the event was filled with inspiring conversations, innovations, and new business opportunities. Oscar Travaglini, the recently-appointed General Manager/COO of Teknisolar, said of the event, “We report particular interest from BIPV module manufacturers, also the main trends point to roof applications for general distribution and bifacial modules for the utility-scale market segment.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.