Japanese industrial technology supplier Toray Engineering is offering coating tools supporting perovskite panels with dimensions up to 1,000 mm × 2,000 mm.

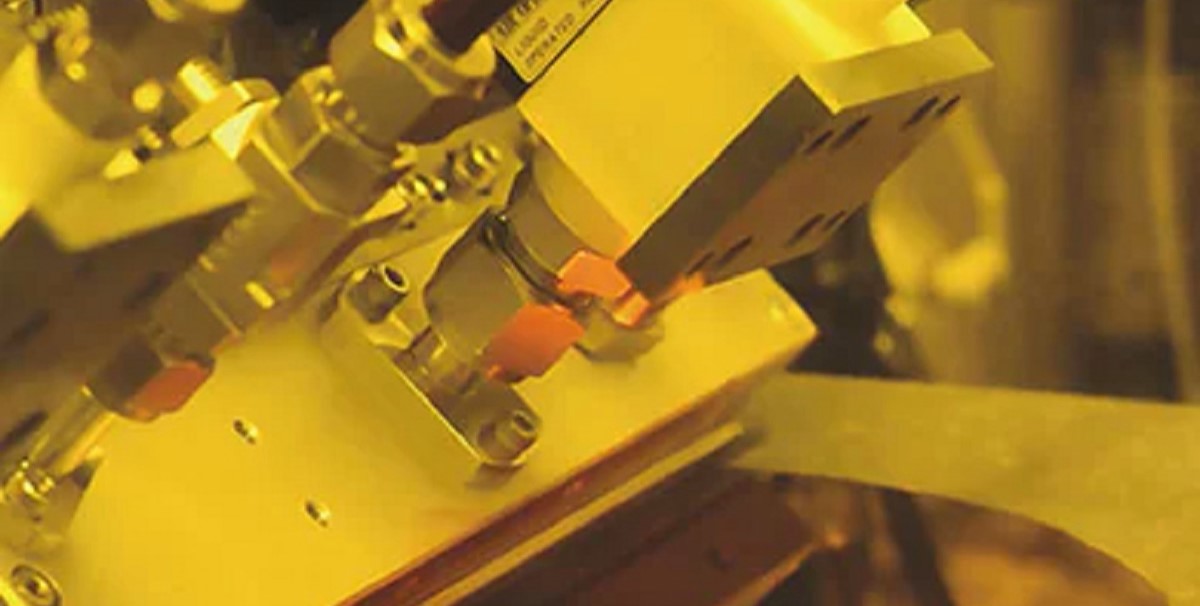

Its slit nozzle coating technology, also known as slot die coating, enables rapid, precise, uniform perovskite thin film coatings for a range of panel sizes, including 1,200 mm × 600 mm and 1,000 mm × 2,000 mm, according to the company.

Toray Engineering will support even larger sizes soon. “The 2,400 mm ×1,200 mm size will be shipped out by the end of this year,” Toray Engineering technical sales account manager, Katsumi Araki, told pv magazine.

The equipment is for large scale production, typically for an in-line process. “We are focusing on sheet-to-sheet production lines today. This is because there is a large market for applications using glass, and there is great potential,” said Araki.

The tools feature low-viscosity liquid handling to 20 coating speed (cp) and a coating thickness of 1 μm. The cp is typically 50 mm/sec. Optional add-ons include vacuum chambers (VCD), an air knife for accelerated drying, and glass transfer robots.

Popular content

The company has a customer for one of its large-sized perovskite solar coaters but it does not disclose the company name, except to say the customer is located in Asia. Araki said that one customer is currently shipping perovskite panels.

Traditionally active in supplying the liquid crystal display (LCD) and organic light emitting diode (OLED) industries, Toray Engineering’s largest coating tools support panels that measure 3,000 mm × 3,000 mm.

Toray Engineering belongs to Toray Industries, a diversified Japanese company, active in the fields of organic synthetic chemistry, polymer chemistry, and biochemistry.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.