A research team at Kafrelsheikh University in Egypt has proposed a kesterite solar cell with an optimized copper oxide (CuO) hole transport layer. Its simulated device had a maximum efficiency of 33.56%.

Kesterite, specifically copper zinc tin sulphide (CZTS) solar cells, are an attractive candidate for affordable thin film solar cells due to the abundance and non-toxic properties of the cell materials and high potential band gaps, according to researchers, but there is a need to improve efficiency.

In the study, the team used SCAPS-1D to simulate a 1.3 eV CZTS n-i-p solar cell to investigate how variations in the thickness, band gap, carrier concentration, and operating temperature of the various layers, including hole transport layer (HTL), electron transport layer (ETL) and absorber layer, impact solar cell performance.

The HTL materials investigated included copper(I) oxide (CuO), copper(I) oxide (Cu2O), and copper(I) thiocyanate (CuSCN).

“By evaluating how these materials affect charge transport, efficiency, and device performance, the most suitable HTL for enhancing the overall effectiveness of CZTS solar cells is identified,” stated the scientists.

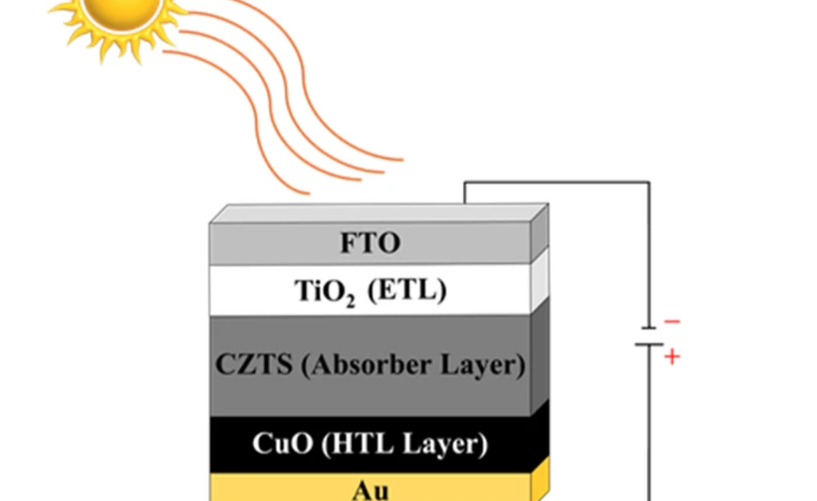

The proposed thin film stack was as follows: a fluorine-doped tin oxide (FTO) front contact, titanium dioxide (TiO2) ETL, CZTS absorber layer, CuO as the HTL, and gold (Au) back contacts.

“Parameters from previous studies were incorporated to analyse the efficiency of kesterite-based solar cells,” noted the scientists. The cell properties were examined at 300 K under standard illumination conditions.

A key finding was that increased operating temperatures negatively affected solar cell performance, with a noticeable decline in efficiency across all configurations as the temperature rose.

After optimising all parameters, the simulation showed a maximum efficiency of 33.56%. The values of open-circuit voltage, short-circuit current density, and fill factor were 1.110866 V, 33.994 mA/cm², and 88.87142%, respectively.

The results confirmed that the ideal thickness to achieve the highest efficiency in this device is 1 μm. The team said that “optimal CuO thickness” improves open-circuit voltage and reduces recombination, noting that if the CuO layer is too thick it generates resistive losses and lower open-circuit voltage and short-circuit current density.

The work was presented in “Numerical simulation and optimization of FTO/TiO2/CZTS/CuO/Au solar cell using SCAPS-1D,” published in nature Scientific Reports.

“The findings from these simulations will serve as an important initial step in identifying the optimal conditions for producing high-efficiency solar devices,” said the team.

It indicated that future research could focus on replacing the CuO with Cu2O as the hole transport layer to “enhance hole mobility and improve bandgap alignment” for greater efficiency and charge transport. It also suggested further research could investigate replacing gold with molybdenum for more sustainable and affordable back contacts.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.