A research team from Delft University of Technology (TU Delft) has developed a new solar module encapsulation technology that uses a liquid and an edge sealant instead of ethylene vinyl acetate (EVA).

“Our liquid encapsulation technology can be applied to all solar cell technology, given that the solar cell is compatible with the liquid. In this work, we have used crystalline silicon (c-Si) solar cells and we plan to extend it to c-Si/perovskite tandem solar cells,” the research's lead author, Urvashi Bothra, told pv magazine. “Currently, we have observed that the technology is robust for mini-modules having 4 cells. Simultaneously, our collaborator Biosphere Solar has been working on upscaling the technology to full size module.”

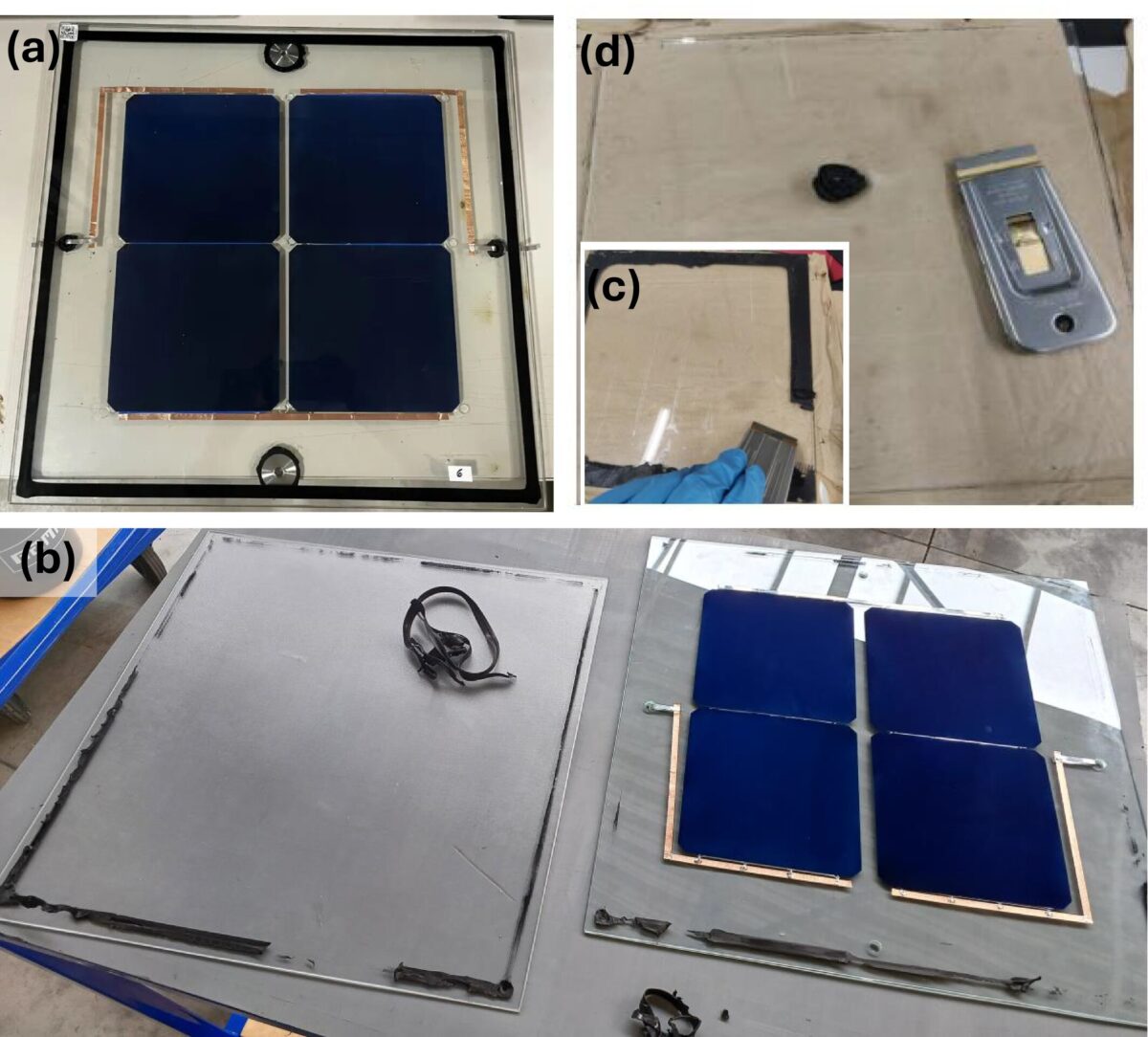

For the experiments, the researchers used front and rear glass sheets measuring 50 cm × 50 cm, supplied by Japanese glass manufacturer AGC Glass.

They tested several liquids, including a silicone oil from US-based Dow; Hydrocarbon-E from Florida-based Engineering Fluids; an ester oil from UK-based MIDEL & MIVOLT Fluids; Hydrocarbon-O from Texas-based DSI Ventures; SP glycol from Dutch supplier InnogreenChem; glycol from Germany-based Labshop; glycerol from Labshop; and deionized water.

Polyisobutylene from German supplier Kömmerling–H.B. Fuller was used as the edge sealant. Commercially available ethylene vinyl acetate (EVA) served as the encapsulant for the reference modules.

The researchers also used 12.5 cm × 12.5 cm Maxeon Gen III interdigitated back-contact (IBC) solar cells supplied by SunPower Corporation, a dogbone connectors from Chinese specialist Qinhuangdao Donwoo Electronic and busbars from Ulbrich.

Image: TU Delft, Progress in Photovoltaics, CC BY 4.0

The researchers soldered the cells using dog-bone connectors and busbars and applied a polyisobutylene (PIB) edge sealant around the bottom glass. The soldered cells were then placed between two glass sheets and laminated in a PV laminator at 95 °C and 400 mbar to fully seal the module without damaging the cells.

Liquid was injected into the air-filled modules through the PIB seal using a syringe, while a second needle allowed trapped air to escape. After injection, the needles were removed, and the PIB seal was resealed with a heat gun.

Modules produced using this method, along with EVA-based panels, were tested under standard illumination and analyzed using electroluminescence (EL) imaging. The researchers also conducted accelerated ageing tests, including damp heat, thermal cycling, and humidity freeze, to assess module reliability.

The analysis showed that liquid-filled PV modules performed comparably to EVA-based modules in terms of efficiency and stability under accelerated ageing. They did not show any loss of performance and offered additional benefits in terms of recyclability and circular design.

The approach was also found suitable for enhancing perovskite/c-Si tandem PV stability, enabling heat management, and integrating into PV-T modules via a liquid heat-exchange loop.

“For a single-cell module, we estimate that the cost of a liquid-encapsulated module is the same as an EVA-encapsulated module. So, the modules cost similar,” said Bothra, when asked about manufacturing expenses.

The novel encapsulation tech was presented in the paper “Liquid PV Module Encapsulation to Enable Circular Design,” published in Progress in Photovoltaics. “Through this study, we aim to put forward new technology for encapsulation and demonstrate that an efficient circular PV module can be achieved with ongoing research,” the scientists said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.