A group of researchers from the University of New South Wales (UNSW) in Australia and Chinese module manufacturer Jolywood has conducted a comprehensive assessment of how laser-assisted firing (LAF) processes influence the behaviour of TOPCon cells under the thermal conditions encountered during soldering, lamination, and high-temperature stress.

“Our findings provide clear guidance for module fabrication workflows and reliability testing, particularly regarding lamination protocols, LAF optimization, and the interpretation of cell-to-module (CTM) losses,” the research's lead author, Bram Hoex, told pv magazine. “We provided new mechanistic insight into why LAF TOPCon cells behave differently from baseline-fired devices during thermal processing, as well as practical recommendations to ensure stable performance through manufacturing and field operation.”

In a previous joint research project, UNSW and Jolywood investigated how effectively the laser-assisted firing process developed by Jolywood itself, the so-called Jolywood Special Injected Metallization (JSIM), enhances the efficiency of industrial-scale TOPCon solar cells by reducing Si-metal contact recombination. The researchers found, in particular, that the manufacturing step can increase cell efficiency by approximately 0.6% absolute compared to the baseline single-step firing process.

In the new paper, titled “Thermal stability of laser-assisted fired TOPCon solar cells: Crucial insights for module manufacturing, certification testing, and field conditions” and published in Solar Energy Materials and Solar Cells, Hoex and his colleagues explained that LAF processes like the laser-enhanced contact optimization (LECO) technique have been adopted in commercial solar module production in recent years and have increased concerns about the thermal stability of the cells.

“We investigated the thermal stability of LAF TOPCon solar cells under both moderate and high-temperature conditions,” Hoex explained. “We found evidence that hydrogen redistribution introduced during LAF is a key contributor to defect activation and contact instability. A three-state defect model is proposed to explain degradation and recovery dynamics.”

The tests were conducted on 182.2 mm × 183.75 mm TOPCon cells fabricated with 130 μm n-type wafers. On the rear side, a tunnelling silicon oxide (SiOx) layer and phosphorus-doped polycrystalline silicon (n⁺ poly-Si) were formed by plasma oxidation and plasma-assisted in situ doping (POPAID). Surface passivation was achieved using aluminum oxide (AlOx) layer deposited via atomic layer deposition (ALD) and silicon nitride (SiNx) deposited via plasma-enhanced chemical vapour deposition (PECVD) on the front, and PECVD SiNx on the rear. Commercial paste and LAF were used for metallization.

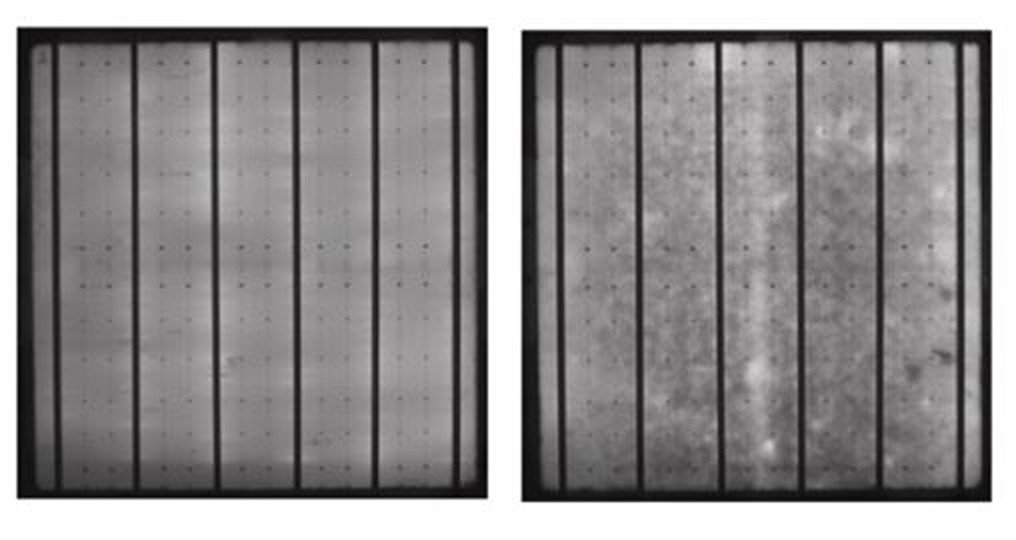

A moderate-temperature thermal test was performed to evaluate cell-to-module (CTM) losses, focusing on two key fabrication steps: soldering and lamination. One group of cells underwent both processes, while a second group was subjected only to lamination for comparison.

The analysis showed that soldering has no detrimental impact on cell performance, but lamination induces a 0.29 % efficiency loss, mainly through fill factor reduction linked to increased J02-type recombination, which is a type of recombination that usually affects fill factor and open-circuit voltage, especially at low and moderate voltages.

The researchers also found that a 1-minute one-sun light soak fully restores the performance, indicating that modules in the field naturally self-recover. “Interestingly, the recovery during light soaking and the degradation after dark storage closely resemble the behaviour observed in samples subjected to ultraviolet-induced degradation (UVID) light, suggesting a possible connection or similarity in the underlying mechanisms,” the scientists said.

The assessment also demonstrated that rapid thermal annealing at 450 C leads to contact deterioration, with fill factor losses reaching up to 21.6 %, but a subsequent LAF step effectively rebuilds the contact and restores performance.

Based on these findings, a three-state defect model and contact degradation mechanisms were proposed for industrial implementation. “These findings provide new insights into the reliability of LAF TOPCon cells and highlight key considerations for industrial processing and module reliability testing,” they concluded.

In June, researchers from the University of Oxford in the United Kingdom and China's metallization paste specialist Changzhou Fusion New Materials identified a new failure mode in LECO-based TOPCon solar modules.

Other research by UNSW showed the impact of soldering flux on TOPCon solar cell performance, that of UV-induced degradation (UVID) in TOPCon cells, degradation mechanisms of industrial TOPCon solar modules encapsulated with ethylene vinyl acetate (EVA) under accelerated damp-heat conditions, as well as the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels.

Furthermore, UNSW scientists investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure, the role of ‘hidden contaminants’ in the degradation of both TOPCon and heterojunction devices, and the impact of electron irradiation on PERC, TOPCon solar cell performance.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.