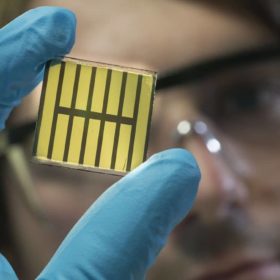

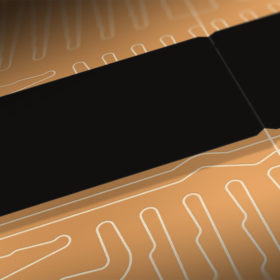

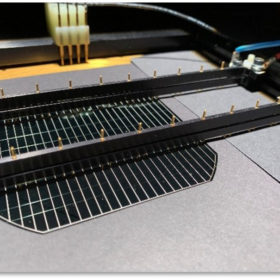

Established thin film processing for 18%-efficient perovskite mini-modules

Scientists in Germany applied vapor-based deposition techniques and laser scribed interconnection – both well established processes in existing thin-film solar manufacturing – to fabricate perovskite mini modules. The group achieved a maximum efficiency of 18% for a device measuring 4cm². Relying on these processes, they say, could simplify processing and reduce losses associated with scaling up to commercial-sized devices.

210mm wafer achieves highest energy yield, finds Trina Solar

Trina Solar has found that its Vertex modules, based on the 210mm wafer, achieve an energy yield up to 1.6% higher than rival products based on the smaller 182mm wafer format. The company conducted outdoor testing at two separate sites with varying climates, finding that products based on the larger format have a particular advantage in low-irradiance environments.

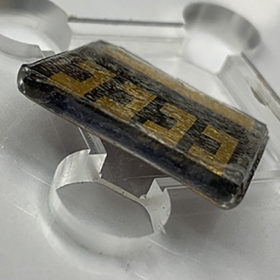

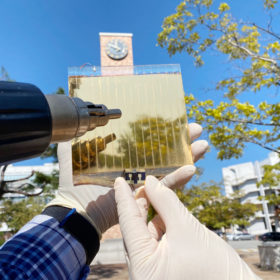

Lead absorbing encapsulant for perovskite solar cells

Scientists in the United States developed what they describe as a ‘scotch-tape like’ solution, which can absorb potential lead leakage from perovskite solar cells, preventing the toxic material from entering the environment. The tape, according to the scientists, can easily be integrated with existing encapsulation strategies, and was shown to absorb 99.9% of lead leaked from cells from that were severely damaged.

Mathematical model to predict rooftop PV system yield

Scientists in India developed a mathematical model to predict the output of solar cells and modules in the field. The model was developed and tested using both sun simulator and actual installed modules. The scientists state that their model can be applied to a PV installation anywhere in the world, and that by taking into account module degradation over time their forecasts can be as much as 26% more accurate than existing energy yield models.

Webinar Q&A: The future of back contact technology

Last month, in a pv magazine Webinar held in partnership with Endurans Solar, we took a closer at Endurans’ conductive backsheet for back contact modules, and examined recent progress in back contact cell and module technologies, and their growing market potential over the next few years. Here, presenters Hugo Schoot, Business director at Endurans Solar, and Bram Verschoor, CCO at equipment supplier Eurotron, answer a more of the questions posed by the audience during the webinar.

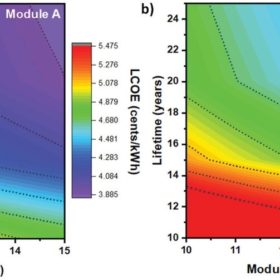

Analyzing the opportunity for perovskite solar module production in India

Scientists in India conducted a techno-economic analysis for a 100 MW production line for carbon-electrode perovskite solar modules, located in Himachal Pradesh, India. The analysis concludes that, even at the smaller scale, this emerging technology could achieve cost levels comparable with today’s silicon solar products.

Scaling up perovskite-silicon tandem solar cell performance

Scientists in Germany investigated various routes to optimizing cell design for perovskite-silicon tandem products. Beyond the perovskite layer itself, they note several other areas that should be optimized for tandem cells, taking silicon heterojunction processing as a starting point. The research identifies several routes to cut costs in cell production, including a significant reduction in indium consumption.

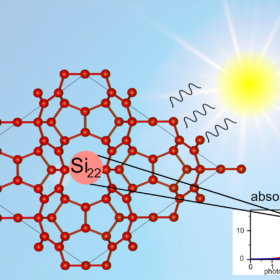

A whole new structure for silicon

Scientists in the United States theorized that a new allotrope of silicon – the same element arranged into a different atomic structure – could show greatly improved photovoltaic performance compared to that used in today’s solar cells. The allotrope, Si22, could also have important properties for use in quantum computing, carbon sequestration and other applications – though fabrication and actual physical testing of the material will be needed to back up the theoretical findings presented so far.

Ambient processed inorganic perovskite solar cells at 19.75% efficiency

Scientists in South Korea demonstrated a fabrication technique for perovskite solar cells relying entirely on room temperature, ambient conditions processes. Using an all-inorganic perovskite material, and a spray coated electron transport layer, cells fabricated by the group achieved a maximum efficiency of 19.75%.

DNV puts different module formats to the test

Energy consultancy DNV was tasked by module manufacturing giant Longi Solar with comparing the balance of systems costs between modules utilizing 182mm and 210mm wafers, based on a 3.7 MW project in three different layouts. The results reveal a slim cost advantage for the smaller of the two, based on both fixed tilt and tracker systems.