With perovskite-silicon tandem cells approaching the 30% efficiency mark, there is plenty of interest in bringing this technology into commercial production. Plenty of work has gone into optimizing the perovskite layer itself for long-term performance and large-scale processing; and now scientists are taking a closer look at how the other important processes in silicon cell production could change when deposition of a perovskite layer is added to the process.

A group led by Germany’s Fraunhofer Institute for Solar Energy Systems (ISE) focused on transparent conductive oxide deposition and cell metallization. These two stages in cell manufacturing are among the most in need of optimization, due to growing concerns over the availability of the indium and silver that’s most commonly used.

The research takes processes used in silicon heterojunction (HJT) cell manufacturing as a starting point, and examines how the addition of a perovskite top cell would change the requirements for the rest of the cell structure. Their full results can be found in the paper Optimized front TCO and metal grid electrode for module integrated perovskite-silicon tandem solar cells, published in Progress in Photovoltaics.

Indium

For the transparent conductive oxide (TCO) layer, which is typically made from indium-tin-oxide, the group finds potential for a significant reduction in material usage. The tandem cells operate at a lower current than silicon alone, and the perovskite top layer has a lower refractive index than silicon, meaning the TCO no longer needs to perform an additional role as an anti-reflective coating. Based on this, the group theorizes that the TCO thickness could be reduced from 75 down to 20 nanometers, resulting in a cost reduction of €0.0146 per cell, or €0.0079 per cell where indium tin oxide is partially replaced with aluminum-zinc oxide.

Popular content

Silver

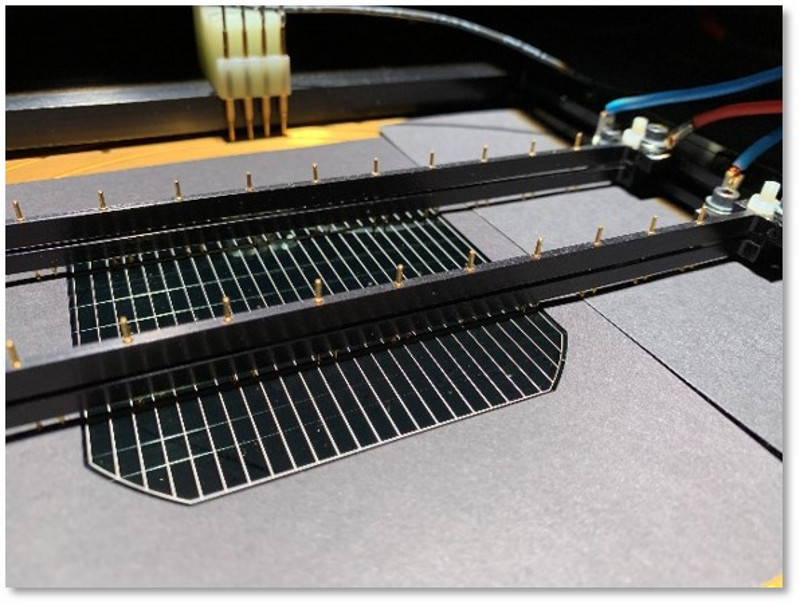

For cell metallization, the group investigated various possibilities for finger width and layout, concluding that the number of wires needed for interconnection could be reduced from 18 to 9 or even less, particularly if a copper plating solution for metallization could be developed. “For a finger metallization with very low-line resistivity, which can be potentially achieved with copper plating, a reduction down to five wires could be possible, given that the contact resistivity of the fingers towards the wires is low enough,” the group explains.

Aside from this possibility, however, the group does not expect tandem cells to bring about a significant reduction in silver consumption. Finally, they note that for both processes the sensitivity of the perovskite means that temperatures in production need to be reduced, from around 220 degrees Celsius used currently in HJT production down to 130 degrees Celsius.

Overall, they find that with optimized TCO and metallization processes, perovskite-silicon tandem cells could reach a levelized cost of electricity of €0.0751/kWh, lower than ISE’s estimate of €0.0849 for today’s single-junction PERC technology.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.