High module prices make Italy an early victim of supply chain disruption

Sergio Matalucci reports for pv magazine from the Key Energy event in Rimini on how the Italian solar market is currently dealing with the module price hike and the supply change disruption. According to the president of Italian association Italia Solare, difficulties to source modules in the market have intensified over the last four months.

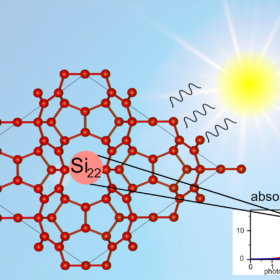

A whole new structure for silicon

Scientists in the United States theorized that a new allotrope of silicon – the same element arranged into a different atomic structure – could show greatly improved photovoltaic performance compared to that used in today’s solar cells. The allotrope, Si22, could also have important properties for use in quantum computing, carbon sequestration and other applications – though fabrication and actual physical testing of the material will be needed to back up the theoretical findings presented so far.

New tech to recover pure silicon from end-of-life solar cells

An Indian research group has used three different chemicals instead of commonly used hydrofluoric acid to separate silicon from the cell. The technique is claimed to be able to deliver recycled silicon with a purity of up to 99.9984%.

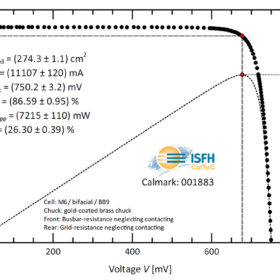

Longi improves efficiency of its heterojunction cell from 25.82 to 26.30% in just one week

The result was confirmed, once again, by Germany’s Institute for Solar Energy Research Hamelin (ISFH).

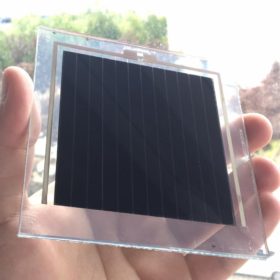

Sunman unveils 430 W glass free solar module

The new product has a power conversion efficiency of up to 19.3% and a weight of 11.2 kg. The module is produced with glass fiber reinforced plastic, which the manufacturer says reduces light reflection and opens up new assembly options.

US solar module imports fall 27% in Q3

The largest single-quarter drop in three years comes as the American Solar Manufacturers Against Chinese Circumvention propose greater tariffs against Asian-imported modules.

Poly and wafer price rises helped GCL with debt pile, seven-months-overdue figures indicate

The polysilicon manufacturer and solar project developer has finally managed to publish the annual figures for 2020 and appears to be placing a lot of faith in its less-energy-intensive granular silicon product. In the meantime, though, another debt repayment deadline is looming within a fortnight.

Perovskite solar cell with improved stability via graphite electrode

The solar cell was built on a fluorine-doped tin oxide substrate coated with titanium dioxide, an electron selective layer made of mesoporous titanium dioxide, a zirconium dioxide insulating spacer layer, and a graphite electrode. A mini-module fabricated with this cell passed, for the first time, a hotspot test.

Module and shipping cost inflation could cost the world 50 GW of solar next year

The input costs of the two biggest contributors to solar plant development expense have gone through the roof since the world began to come out of Covid-19 lockdowns, to leave project developers with some difficult choices.

Polish distributor launches 250 MW module procurement in response to rising solar panel prices

Menlo Electric said the procured modules will be primarily offered to B2C and B2B installers across Central Europe.