GCL enters ‘final phase’ of its great project sell-off

The solar farm development unit owned by the poly maker sold off 2 GW of photovoltaic generation capacity in China in the first six months of the year but has confirmed more sales lie ahead.

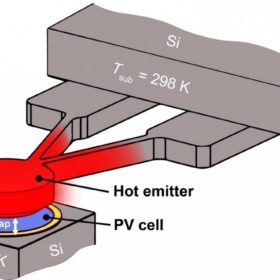

Novel approach for thermophotovoltaics promises higher efficiencies

U.S. researchers have proposed a new approach to fabricate solar thermophotovoltaics (STPV) with higher power densities. The novel technique consists of reducing the distance between the emitter and the solar cell to a nanoscale.

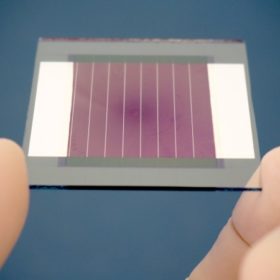

Single crystal perovskite solar cell with 17.8% efficiency

The solar cell was manufactured with crystals that were grown directly onto indium tin oxide (ITO) substrates covered with hole transport layer (HTL). These substrates have a controlled thickness of tens of micrometers and area of tens of mm2. The device showed an efficiency of 17.8%, a short-circuit current of 21.0 mA cm−2, an open-circuit voltage to 1.08 V, and a fill factor to 78.6%.

Debate over US solar safeguards starting to heat up

The governments of Mexico, Malaysia, and Turkey – along with the Solar Energy Industries Association, NextEra Energy Resources, REC Americas, and other companies – are chiming in to have a say in a recently reignited debate in the U.S. solar market.

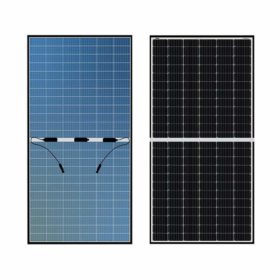

Loom Solar unveils 440W/530W bifacial modules

India’s Loom Solar has launched its Shark line of bifacial PV modules for rooftop projects. The nine-busbar panels have power outputs ranging from 440 W to 530 W, with front-side efficiencies ranging from 20% to 21% and rear-side gains of up to 20%.

Chinese PV Industry Brief: Trina shipped 10.5 GW of modules in H1

Moreover, the Chint group said its PV plant fleet in China has reached a combined capacity of 6.54 GW and project developer China Shuifa Singyes said high polysilicon prices and Covid restrictions had caused a revenue drop.

Photovoltaic sunshade based on perovskite solar cells

The phovoltaic sunshade was deployed on the facade of a factory owned by Polish aluminum system provider Aliplast. The movement of the PV blinds is regulated by a controlling system linked to a weather station installed on the roof.

Mini organic solar module with 13.94% efficiency

The panel is based on 14.9%-efficient organic PV cells with a surface of 1.1 cm2 that the same research group unveiled in September 2020. The solar cells were interconnected using laser structuring.

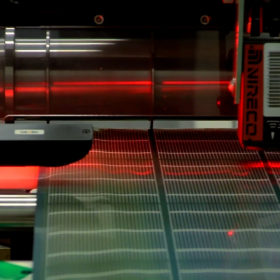

Fraunhofer CSP develops repair process for PERC solar cells

The performance of the solar cell contacts can be improved with laser-assisted current treatment. The process does not damage the solar cells but only optimizes faulty semiconductor-metal contacts.

Increasing volumes for PV module recycling in Brazil

Brazilan PV module recycling specialist SunR has already recycled 30 tons of panels and expects to receive another 125 tons. According to its CEO, demand for recycled panels, especially broken panels, has increased considerably in recent years.