Perovskites stick together for better performance

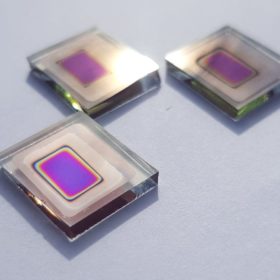

Scientists in the U.S. demonstrated an additive that acts as a “molecular glue” within a perovskite solar cell. Treating the cells with this self-assembled monolayer material was shown to greatly improve their long-term performance, whilst also providing a boost to conversion efficiency. And the scientists further point out that the treatment relies on simple processing and readily available materials – good signs for its applicability in manufacturing.

Jolywood signs mega-deal to supply 7 GW of household solar

Based on the price agreed for the first year of the five-year contract, the total deal would be worth almost $4 billion to the $1 billion company. However, with input costs rising and the state-owned sponsor likely to expect to pay lower fees for subsequent years, the TOPCon manufacturer’s margins may not remain so fat.

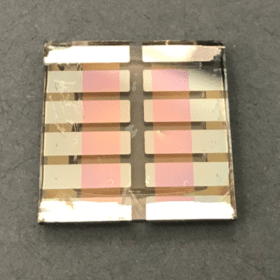

Organic solar for optical wireless data receivers

Researchers in the United Kingdom have built a 14%-efficient organic PV device that can be used in high-speed optical wireless communication systems. The cell consists of a 4×2.5mm photoactive layer fabricated with a bulk heterojunction of a polymer donor and fullerene and non-fullerene acceptors.

The weekend read: Life after PERC

The pursuit of higher conversion efficiencies is an eternal theme in the PV industry. Among all the links in the chain, cell technology is the most fundamental and decisive element. As we look beyond the established PERC technology, whether heterojunction or TOPCon will become the dominant “next-gen” solar cell among China’s manufacturing giants is emerging as a balancing act between incumbent and upstart, reports Vincent Shaw from Shanghai.

Chinese PV Industry Brief: Tongwei raises cell prices, Longi joins forces with Engie

The Chint Group has also said it was China’s largest PV plant owner at the end of 2020 with more than 5.7 GW in operation.

CNBM wants to set up GW-scale production of CdTe solar panels in China

German PV production equipment provider Singulus will supply the vacuum coating systems for the new production. The Chinese conglomerate currently operates CIGS panel production facilities at four different locations in China.

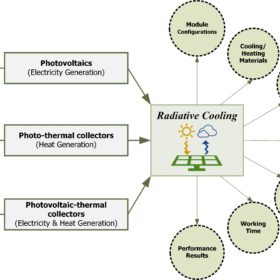

The best radiative cooling tech for PV arrays

Scientists in China have analyzed the radiative cooling techniques used in combination with solar energy systems such as PV arrays, solar thermal collectors, and concentrated PV installations. They identified five major system typologies based on functionality and working time.

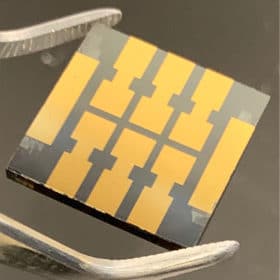

Semitransparent selenium solar cell for applications in tandem devices

The bifacial device showed a power conversion efficiency of 5.2% on the front side through an n-type contact and 2.7% on the rear side through a p-type contact.

Webinar Q&A: A recipe for improved performance

In a recent pv magazine webinar, module degradation experts took our audience through the role of temperature and mechanical stress in causing modules to under-perform. We were treated to a look at some impressive results for modules integrated with Coolback – a solution that replaces the backsheet/rear glass and frame in a conventional panel and promises lower operating temperatures and better mechanical strength. Here, Simon Meijer and Alex Masolin, from Coolback – along with Fraunhofer ISE’s Andreas Beinert – answer some of the questions we didn’t have time for during the live broadcast.

Industry reacts to India’s production-linked PV incentive scheme

Indian solar manufacturers have welcomed the bidding criteria for incentives to set up gigawatt-scale, high-efficiency PV production lines, but said that they would like a bigger budget to finance significant capacity build-out.