Solar-plus-storage signaled by Xinyi internal sales

Lithium-ion battery products will be sold by the group’s storage and autoglass business to its solar glass operation–for use in solar project development–and its float glass manufacturing unit.

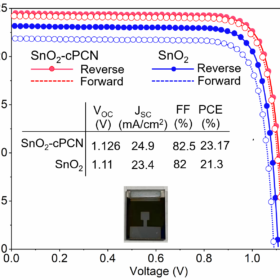

Perovskite solar cell with larger grain size and 23.17% efficiency

The result was achieved for a small area device with the size of 0.1 sq cm. The cell was fabricated with a Tin(IV) oxide electron transport layer modified with crystalline polymeric carbon nitrides (cPCN).

Hair! Coming to a next-generation PV cell near you

Scientists have found that a human hair derivative can protect, stabilize and enhance the performance of perovskite solar cells.

Jinko shipped 18.7 GW of modules in 2020

The Chinese module manufacturer saw its net profit rise only slightly last year, despite a larger increase in turnover and shipments. It expects to almost double its shipments to up to 30 GW of PV modules in the current fiscal year.

Chinese PV Industry Brief: Akcome achieves 24.2% efficiency for heterojunction cell in mass production

The solar cell manufacturer claims to have achieved the record efficiency at its 2 GW Huzhou, in northern Zhejiang province. Meanwhile, PV production equipment supplier Jinchen is raising funds for the development of its plasma-enhanced chemical vapor deposition (PECVD) technology for heterojunction cell production lines.

Vehicle-integrated PV for light commercial vehicles

A German consortium is building a light commercial truck prototype powered by 10 PV modules featuring Meyer Burger’s heterojunction cells. Initial estimates suggest that the panels could cover more than 25% of a vehicle’s total annual driving distance, and researcher Robby Peibst told pv magazine that the vehicle-integrated photovoltaic market could hit 5 GW by 2030.

Tata Power Solar expands cell, module capacity

Tata Power Solar, a PV manufacturer and EPC contractor, has added new lines to its factory in Bangalore, India. It is widening its product range to include half-cell and bifacial mono PERC panels.

PV rides through semiconductor chip shortage

Many industry sectors across the world are currently being hit by a semiconductor chip shortage as major manufacturers are unable to meet demand. According to Cormac Gilligan, an associate director at IHS Markit, solar and energy storage manufacturers are being less affected. In general, the solar and energy storage industries have learned lessons from being impacted by semiconductor components, for example, transistors, capacitors and resistors in prior years, Gilligan told pv magazine.

Chinese solar company highlights credit downgrades of state-owned entities

A record number of defaults last year has spooked some lenders, according to Solargiga, but the solar manufacturer has announced ambitious plans to ramp production capacity this year and next.

P-type TOPCon solar cell with 21.2% efficiency

Fraunhofer ISE scientists have identified the best metallization pastes to help reduce contact resistivity and contact recombination in p-type TOPCon solar cells. They applied a silicon nitride layer through plasma-enhanced chemical vapor deposition onto both sides of a cell.