Panasonic abandons Chinese solar manufacturing tie-up

The Japanese electronics giant said a partnership with GS-Solar will not materialize and it will continue producing its modules in Japan and Malaysia while seeking other cooperation opportunities.

The PV world ten years ago – summer series part I

pv magazine editor Pilar Sánchez Molina recollects everyday news from the PV sector of ten years ago as part of a new series. The insights offered will not only bring back memories for the pioneers of that exciting, challenging period but may also offer an idea of where we could be in 2030.

Wacker CEO hits out at Chinese rivals

Rudolf Staudigl highlighted polysilicon manufacturing overcapacity among Chinese competitors as he announced Covid-19-battered second-quarter figures for the Munich-based chemicals conglomerate.

REC Silicon sells off last remnants of Moses Lake polysilicon

The Norwegian company mothballed its Washington State facility more than a year ago and is now reliant on semiconductor-grade poly and silane gas produced at its fab in Butte, Montana – a facility for which the business says it has received plenty of interest from potential purchasers.

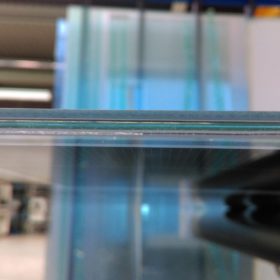

Chinese PV Industry Brief: PV glass supply deals, bonds to finance solar incentives

Two solar glass makers kicked off the week with new deals and solid earnings reports while the Chinese government revealed it may issue bonds to fund clean energy incentives.

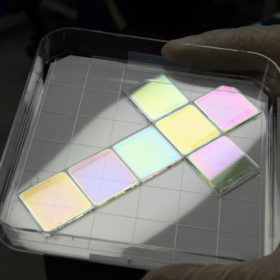

CPV panels for agrivoltaics

Swiss startup Insolight has raised €4.6 million to bring its concentrating PV module technology to commercial production. The panels have a claimed efficiency of 30% and power output of 160 W. Originally conceived for rootop solar, the product is now being recommended as an interesting option for agrivoltaic projects.

Suntech to reach 10 GW of module capacity this year

The Chinese manufacturer has completed the first, 1.5 GW phase of a 10 GW expansion plan. It will deploy another 4 GW phase by the end of this year at two new facilities in China’s Jiangsu province.

Scratching the surface of LeTID

The mechanisms behind light-elevated temperature-induced degradation are still not fully understood, but it is known to cause significant performance losses for modules in the field. Scientists in China are investigating the causes of the phenomenon, and are currently focused on the surface of the materials and the interfaces between the silicon and passivation layers.

Chinese solar glass company keeps 24-hour furnaces running during Covid crisis

Xinyi Solar has revealed another impressive set of figures and plans another 1,000-ton-per-day production line this month plus a new mine to source raw materials in September.

Cadmium-free CIGS solar cell with 18% efficiency

South Korean scientists manufactured the cell with the chemical bath deposition method, using different thiourea concentrations. For the buffer layer, they used zinc instead of cadmium sulfide. The cell is flexible and is available in seven different colors.