Tesla unveils a bigger, better, simpler Solar Roof – at a 40% discount

Elon Musk has officially launched the third phase of his crusade to make a successful solar roof tile, with promises that this time it is going to be a success.

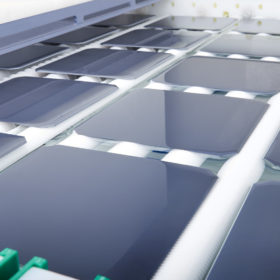

German supplier fields orders for 10 GW of PERC cell production lines in three months

RENA Technologies may struggle to feed the insatiable demand for production capacity in China fast enough and has welcomed orders worth ‘tens of millions of euros’ from three big clients.

Kalyon Enerji finds Chinese partner for 500 MW module fab in Turkey

The factory, backed by the Turkish government in September, was originally intended to be built with the support of Korean solar manufacturer Hanwha Q Cells. The new partner is China Electronics Technology Group Corporation (CETC). Production is planned to start next year.

Bangladesh extends incentive scheme for domestic solar industry

PV manufacturers receive 10% of the value of their exported products as an incentive and the nation’s central bank has extended the program to cover this financial year. Bangladesh’s solar manufacturers have called for more, however, and point to more generous schemes to the west.

Runergy plans another 6 GW of mono PERC manufacturing capacity by 2022

The fact solar manufacturers in China are still aggressively expanding output illustrates the strength of global demand for PV even as hopes for a rebound in Chinese installations appear to have been groundless.

The weekend read: A lead-free future for solar PV

Lead plays an important role in crystalline silicon module manufacturing when it comes to cell interconnection. But even in small amounts, the presence of this toxic material in a PV module could be viewed as a black mark against the industry’s sustainable credentials. Alternatives are available, but it seems the price is not yet right for broader uptake.

Meyer Burger raises another $14m by selling software subsidiary

The Swiss solar equipment maker has already sold its corporate headquarters this week as it aims to generate a fighting fund until the hoped-for returns of a European PV manufacturing renaissance materialize.

First Solar is sold out through mid-2021

The thin film PV maker has reported solid third-quarter results after the opening of its massive, 1.3 GW factory in Ohio.

China’s much-trailed second-half solar rebound has failed to materialize

The world’s solar superpower added only 16 GW of new generation capacity up to the end of last month, according to the head of the main industry association. Short of a ten-week miracle, the annual capacity figure seems set for a second consecutive steep annual decline.

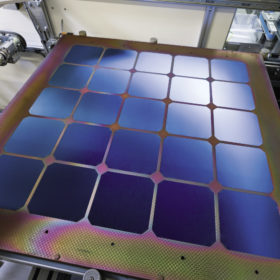

Enel kicks-off production at Italy’s heterojunction module factory

The manufacturing facility, idled a few years ago, will produce bifacial modules. The company claims panel efficiency exceeds 20.5% and the factory has an annual production capacity of around 200 MW.