Longi unveils results of bifacial module test

The exercise, conducted on Longi PERC bifacial modules by Germany’s TÜV SÜD at a test field in China, showed surprisingly higher gains in panels getting light reflection from painted-surface and grassland albedo. It also showed, Longi claimed, bifacial panels operate at lower temperatures than single-sided alternatives.

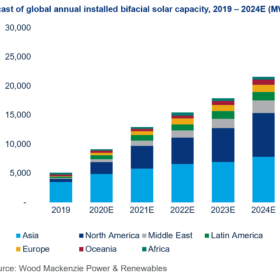

WoodMac: Bifacial module capacity will exceed 21 GW by 2024

Increasingly affordable and free from the Trump administration’s solar tariffs, bifacial modules are only set to get more popular in the years ahead. In its first report on bifacial PV, WoodMac predicted the technology will make up 17% of global installations five years hence, quadrupling the share it will have this year.

The ballooning potential of curved solar cells

Researchers in the U.S. claim to have developed a manufacturing process based on the use of a latex balloon that could lead to the production of more efficient curved electronic devices, including hemispherical solar cells.

Bigging UP the carbon-free pioneers: Step forward 3S Solar Plus

pv magazine’s UP campaign aims to highlight industry movers who embrace carbon reduction and the circular economy in their operations and Swiss BIPV manufacturer 3S Solar Plus boasts an impressive sustainability record.

Jinko ships 300 MW for project in southern Spain

The Chinese module manufacturer has provided Cheetah panels for the Talasol project in the municipality of Talaván, near Cáceres in the southern Spanish region of Extremadura.

Jinko becomes first solar manufacturer to make 100% renewable energy pledge

The Chinese module giant has committed to sourcing 70% of its energy from renewables by 2023 and all of it by 2025. If serious, that could represent confidence in the amount of new renewable energy generation capacity to come online in China given the company’s huge production capacity expansion plans.

Hanwha Q Cells opens largest solar factory in the Western Hemisphere

The 300,000 sq ft factory in Dalton, Georgia has the capacity to produce 12,000 PV modules per day – 1.7 GW worth annually for panels able to produce the same peak generating capacity as the Hoover Dam.

International Energy Agency forecasts 115 GW of new solar this year

The global expansion of PV, wind power and other clean energies will see double-digit growth this year as solar continues to lead the pack.

Live fast, die young: MIT study proposes use of 10-year panels

Research has found even short-lived, 10 to 15-year solar panels could provide enough return for bankable projects. The researchers believe panel costs, coupled with an industry mindset now fixed on the final solar energy price rather than costs per kilowatt installed, may open opportunities for PV products currently snubbed because of a short lifecycle.

UK scientists find way to cut down indium

A research team led by the University of Liverpool has developed a transparent conductive oxide material to replace tin with molybdenum. The results demonstrated better performance and potentially lower material costs than the transparent conducting layers used in today’s commercial solar cells.