First Solar sees a doubling coming in 2019

The thin film PV maker projects 5.4 to 5.6 GW of module shipments next year, more than double its current projected 2018 volumes of 2.6 to 2.7 GW.

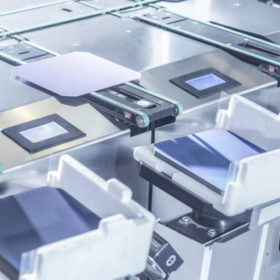

German equipment suppliers report ‘strong’ bookings for cell, thin film segments

In its Q3 2018 report, VDMA finds that German PV equipment providers are continuing to enjoy much improved fortunes compared to the previous year. Solar cell and thin film equipment suppliers account for the vast majority of bookings.

Greatcell Solar enters administration

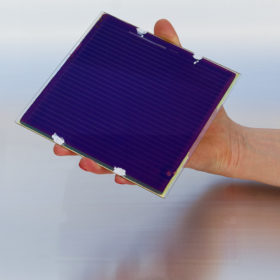

Australia-based perovskite solar cell specialist Greatcell Solar has failed to secure refinancing for its activities and has been forced to appoint administrators. The company lays the blame at the federal government’s door, pointing to the R&D rebate changes and policy settings that are unsupportive of renewable energy investment as the reasons behind its downfall.

Sentis Capital urges Meyer Burger to establish GW-scale HJT production

Meyer Burger’s largest single shareholder has requested the company change strategy. Sentis Capital has urged the Swiss technology company’s board to raise sufficient capital for it to set up its own GW-sized production facility for its heterojunction and tandem cell PV technology. Meyer Burger has responded that it is view of only one shareholder.

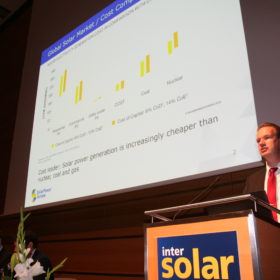

Global-PV market: demand increasing – prices largely stable

According to EnergyTrend and PV Info Link, the downward spiral of prices along the PV value chain has come to a halt. Nonetheless, by bringing together the two pieces of recent market analysis, regional and value chain variations can be observed.

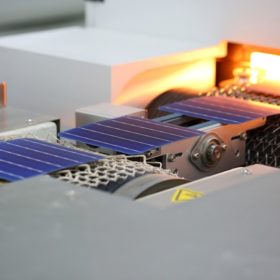

UNSW, Leadmicro to partner on ALD for PERC production

UNSW Sydney has partnered with Leadmicro to develop the next generation of PERC solar cells and fast-track their time to market. The Chinese PV production machinery manufacturer is donating $1 million Atomic Layer Deposition (ALD) reactor to UNSW to test and adapt a new process for PERC cell solar cell production.

New plans by VW, Tesla and BYD support predictions that EV sales are set to skyrocket

A number of significant manufacturing and investment plans in China, Germany and North America by major automobile makers VW, Tesla and BYD are backing up predictions that electric vehicle car sales are set to skyrocket in the coming decades.

Seraphim expands South African solar cell fab plans to 500 MW

Chinese solar manufacturer Seraphim has announced plans for a 500 MW cell factory in Port Elizabeth, South Africa. The company also plans to expand an existing 300 MW module factory in South Africa’s Eastern Cape region by 200 MW.

SolarPower Europe calls for 5 GW of EU solar module manufacturing

The European solar association has called on Europe to set up 5 GW of solar PV module manufacturing capacity to cater to the expected around 15 GW of annual demand.

EU-funded initiative set to launch new anti-soiling coating

A project backed by the European Union’s Horizon 2020 program says it has developed a self-cleaning coating for modules which is also anti reflective and weather resistant. The project – SolarSharc – expects to launch the product next year.