Exide Industries, Leclanché announce JV for battery manufacturing in India

India’s Exide Industries Limited and Switzerland-based Leclanché S.A. have announced a 75%-25% joint venture (JV) under which lithium-ion (Li-ion) cells, modules and battery packs will be manufactured in the state of Gujarat.

LG to make high-efficiency solar panels in the US

LG Electronics has announced plans for a 500 MW/year solar module manufacturing facility in Huntsville, Alabama. The facility will assemble the manufacturer’s 19.8% efficient NeON2 60-cell 340-W panels for residential applications.

Singulus to develop next gen CIGS production system for Avancis

Both solar companies are closely linked with the Chinese state-owned company, CNBM and they now want to work together to develop the next generation of CIGS manufacturing facilities.

GT Advanced Technologies opens silicon carbide factory in US’ New Hampshire

The upstream technology company plans to sell silicon carbide for applications including advanced inverters for solar and battery storage, as part of a new emphasis on materials supply.

JinkoSolar posts lower shipment volumes, revenues for Q1, remains optimistic despite policy change

As forecast in its 2017 financial report, JinkoSolar shipped around 2 GW of modules in the first quarter of this year. Meanwhile, it did not adjust its forecast for 2018 shipments, in the range of 11.5 GW to 12 GW, despite the Chinese government’s cuts to installations.

Ambitious PV expansion plans for China’s Tongwei, Longi and Sunport still on track

Many expansion plans are still firmly afoot in the Chinese solar PV manufacturing industry, if the information pv magazine gathered from some of the country’s leading manufacturers at last week’s Smarter E event, is anything to go by. Indeed, Tongwei , Longi, Sunport and BYD are all progressing at full speed with their capacity ramp ups.

Solar trade dispute: US agrees consultation with Korea, EU, China, Malaysia and Thailand

Through the consultation, the U.S. aims to settle the dispute over the 30% import tariffs, introduced under Section 201.

REC Group launches new half-cell solar module

At last week’s Intersolar Europe show in Munich, Norwegian headquartered manufacturer REC Group unveiled its latest module innovation, the N-peak series. The new solar PV modules will be the first to combine n-type, mono-cSi and half-cut cell technologies.

The weekend read: Heads you win, tails you win

One manufacturer after another has announced bifacial modules, and buyers would do well to consider the benefits. Independent calculations show that increases of up to 15% or more are realistic in countries such as Germany.

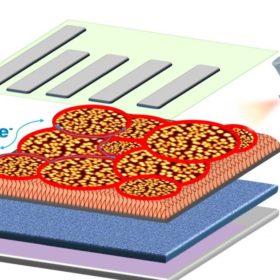

Researchers turn to spray coating in applying ETL to perovskites

Perovskites, a tempting low-cost alternative to crystalline silicon based solar cells, could be moving closer to commercial production thanks to a new way of applying the critical electron transport layer (ETL) pioneered by an international team of researchers.