Manz to partially resume operations after Easter

The PV production equipment manufacturer said its employees will return to work at to two locations in Germany as planned after the Easter break, despite concerns about the Covid-19 pandemic.

Software for virtual power plants powered by residential solar-plus-storage

With its sonnenVPP, German battery company Sonnen wants to improve the efficiency of virtual power plants which it says can offer primary balancing energy from houses with solar and storage and can operate up to 90% more cost-effectively.

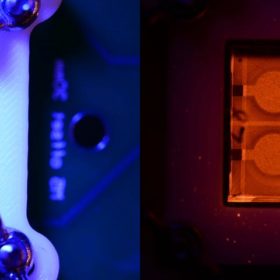

Shine! You’re on photoluminescence camera!

Researchers in Australia and China used intensity-modulated photoluminescence to map the series resistance of perovskite solar cells with a technique which could further understanding of the causes of instability issues in such devices.

A big grid solution to harness small solar arrays

Scientists at the U.S. National Renewable Energy Laboratory are developing a communication system to coordinate and control the volumes of solar power injected into grids by small scale solar arrays.

Australian researchers enhance clean hydrogen electrolysis

Griffith University scientists have unlocked a catalytic process to enhance the breakdown of water into hydrogen and oxygen and bring Australia a step nearer clean, efficient hydrogen fuel.

All-organic, sustainable proton battery from Sweden

A group of scientists at Sweden’s Uppsala University have developed a proton battery based on abundant organic materials. They say the battery can be charged “in a matter of seconds” while operating at low temperatures, and can be cycled more than 500 times without significant capacity loss.

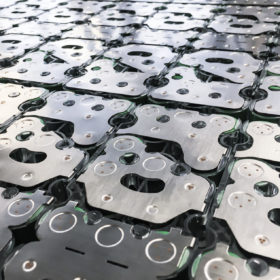

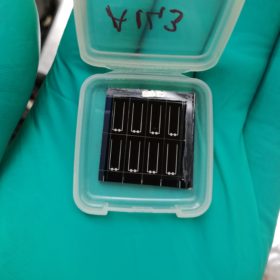

New process for kesterite solar cells with 10% efficiency

German scientists have developed a new process for the formation of a phase pure kesterite Cu2ZnSnSe4 (CZTSe), which they claim can improve the material homogeneity and suppress the well-known issue of tin losses. The new technique is based on stacked elemental and alloyed precursors with a Zn/Cu-Sn/Zn precursor structure.

Fraunhofer ISE tests vehicle-integrated PV in commercial trucks

Two Fraunhofer institutes and four industrial players are working together to develop a concept that will facilitate the use of vehicle-integrated solar modules in electric vehicles and trucks. The three-year “Lade PV” project will also focus on PV components and manufacturing processes.

Using ultrasonic irradiation to separate backsheets in PV waste

Chinese researchers have used an industrial-grade, 720 W ultrasonic cleaner – with a frequency rating of 28 Khz and 1,000 W of heating power – to separate backsheets from end-of-life PV modules. They’ve concluded that an ultrasonic power of 720 W is ideal for the separation process.

Waves, wind & floating PV

Dutch research center TNO is setting up a test facility for floating PV plants in Oostvoornse, where it will analyze the impact of wind and waves on floating structures and module yield. TNO Senior Project Manager Jan Kroon told pv magazine that it will assess module damage and the impact of waves on light absorption. It has already found that the ratio between wave-height and wave-length is a key factor in mismatch losses, while noting that optimizers and micro-inverters on panels could mitigate losses.