German scientists develop solar facade with 50% higher yield

The three-meter prototype consists of nine panels based on an aluminum compound. The PV elements of the facade can be tilted to capture more sunlight.

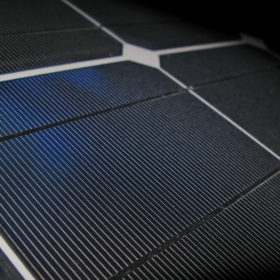

A commercial bifacial HJT solar cell with 24.1% efficiency

The cell is being manufactured by Switzerland-headquartered Ecosolifer with a manufacturing line provided by heterojunction specialist Meyer Burger at a 100 MW factory located in Hungary. The claimed efficiency is yet to be confirmed by an independent party.

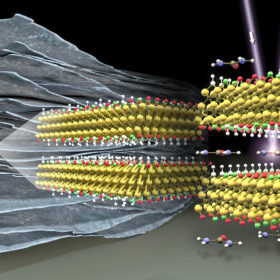

Speeding up storage with pseudocapacitors

Scientists at Germany’s Helmholtz Zentrum Berlin have made a discovery they say could greatly increase the energy storage capacity of titanium-based ‘MXene’ pseudocapacitors, ultimately leading to faster-charging batteries. The group found adding urea molecules between MXene layers increased the material’s storage capacity by up to 56%.

Achieving 21.2% efficiency in a perovskite cell thanks to food additives

South Korean scientists have developed two perovskite solar cells based on a polymer made with peppermint oil and walnut aroma food additives, respectively. The new dopant‐free hole transport polymer is said to enable longer durability of the devices and to prevent lead-leakage.

A new PV emulator to evaluate the I-V profile of solar panels

The device is based on a state-feedback adaptive control system in a real-time controller. According to its developers, it can achieve good dynamic response and boasts better bandwidth than current commercial alternatives.

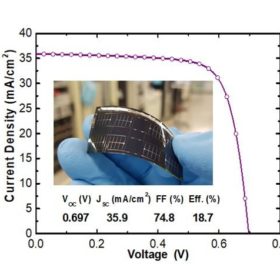

Korean researchers announce flexible CIGS solar cell with 20.4% efficiency

The thin-film cell was manufactured through a low-temperature process and doping with alkali elements.

Coronavirus concerns overshadow PV Expo in Tokyo

The annual trade show was not particularly well-attended this year, but market sentiment is still positive in Japan – nobody believes that installations will drop due to the coronavirus outbreak. And the country’s upstream industry – modules, batteries, and hydrogen tech – clearly remains compelling, given the number of brave souls who actually did make the trip out to Tokyo Big Sight this year.

Quantum dot hybrid HTJ cell with 12.82% efficiency

South Korean researchers have developed a hybrid tandem solar cell based on quantum dots and organic bulk heterojunction (BHJ) photoactive materials. They claim that the cell could reach an efficiency rate of around 15% if they continue to reduce energy losses in the quantum dot cell and enhance near-infrared absorption.

Integrating stress and temperature sensors in crystalline silicon cells

Fraunhofer ISE researchers have integrated stress and temperature sensors within a PV module. They claim that the devices cover a very minimal part of the cells, and that their interaction with the module and the cell itself is quite limited. The sensors can be manufactured as part of a regular cell manufacturing process.

Trina unveils two 500 W bifacial solar modules

The Duomax V and Tallmax V panels are equipped with glass-glass and glass-backsheet frames, respectively. Both offer a reported 21% efficiency and orders will be taken from the second quarter on. Trina plans to have a combined 5 GW of annual production capacity for the products this year.