The weekend read: The rise of M6

The shift to the larger M6 wafer format could occur faster than many have expected. Promoted heavily by mono giant Longi, the format is said to be a good fit for both cell and module production, while still allowing for relatively trouble-free integration into PV arrays. And it all began in China.

Watch how to improve perovskite solar cells in 2D!

Saudi researchers claim to have improved the thermal stability and moisture resistance of such devices by replacing 3D hybrid perovskite with two-dimensional compounds. They used organic compound ethanolamine, which is said to provide better results in slowing down the hot-carrier cooling process.

New process could yield 26.6% efficient IBC cells

Researchers in Germany are trialing a host of new processes and materials to develop interdigitated back contact solar cells. A deposition technology named ‘hot-wire’ chemical vapor deposition, is said to provide excellent passivation without the need for treatments such as recrystallization or hydrogenation.

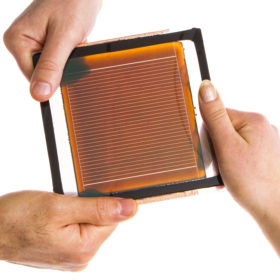

Perovskites meet the stability standard

European research group Solliance says its perovskite modules have passed three key industry standard reliability tests: Light soaking, damp heat and thermal cycling. The group said it is the first time perovskite modules of that size have achieved such results and represents a milestone in the technology’s move toward commercialization.

Solving seasonal storage with aluminum cycling

Scientists at Switzerland’s University of Applied Sciences Rapperswil have demonstrated an aluminum conversion process which could be valuable for long-term renewable energy storage. Simulations suggest that by employing the process, a new multi-family building in Switzerland could meet all its energy demand from a 7-11 kWp solar system.

A new front electrode structure for shingled PV panels

Researchers in Korea have proposed a new design for dividing and bonding which is said to provide higher efficiency from fewer fingers. The number of fingers optimized for division into five cells was 128 and for three, 171. Five offer power conversion efficiency of 17.346% and three 16.855%.

A new strategy to mitigate voltage spikes in small solar systems

The approach combines virtual impedance and a modified pulse-width modulation strategy to suppress fault currents in grid-connected PV systems.

The best way to predict the I-V profile of PV panels

A study has considered the best mathematical models for predicting solar module performance under varying conditions.

Lead-free soldering in modules: It can be done!

pv magazine’s UP sustainability campaign has investigated the use of lead in PV panels and found, with soldered cell interconnections in particular, viable alternatives are scarce. However, German headquartered manufacturer Opes Solutions has launched a small module for the off-grid market featuring lead-free solder, developed at the request of a customer. We caught up with Opes CEO Robert Händel for a closer look at the module and the challenges and benefits of going lead-free.

Panasonic claims 16.09% efficiency for lightweight perovskite solar module

The device has an area of 802cm² and thickness of 2mm. The manufacturer claims it improved module performance through an inkjet coating method and a reduction in weight by using thin glass substrates.