Shell to build 100 MW hybrid wind-solar project

Shell plans to construct a 50 MW solar park and a 50 MW wind farm in the Netherlands. It said the two installations will share the same connection point.

Mondragon to supply 100 MW module production line to Solarge

Mondragon will install a 100 MW manufacturing line in the third quarter at Solarge’s factory in the Netherlands. Production is scheduled to start by the end of this year.

Fortescue provides backing for Dutch PV module maker

Fortescue Future Industries continues to advance its green energy ambitions, announcing it will provide new funding for Dutch solar PV module maker HyET Solar, in a move designed to accelerate a planned expansion of the company’s manufacturing plant in the Netherlands.

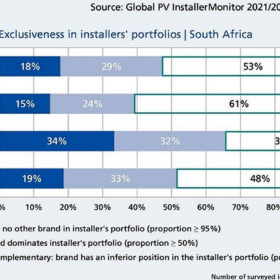

Module brands that earn the trust of solar installers

The latest global PV installer survey by Germany’s EUPD Research offers a hint of the solar brands which installers, mostly based in Europe, gravitate toward. This year’s report also ventured to South Africa and considered mounting systems for the first time.

Grid company appeals for flexibility from energy consumers

Tennet has suffered well-cataloged problems attempting to absorb solar projects into parts of its Dutch grid network and is now appealing for help in two pinch provinces.

Atomic layer deposition tool for perovskite cell pilot line

Dutch equipment supplier SALD has announced delivery of a spatial atomic layer deposition system to an unnamed customer in the United States. The tool will be used in the pilot-scale production of perovskite solar cells. While it has not disclosed the exact function of the tool within the pilot project, it said it will be used to deposit thin coatings to protect cells from damage in later manufacturing stages, and ensure their longer-term stability.

Long-duration storage solution based on saltwater

Developed by Dutch start-up AquaBattery, the storage technology is claimed to independently amend power and energy capacity. The battery system utilizes three storage tanks, one with fresh water, one with concentrated salt water and one with diluted salt water, and also relies on membrane stacks.

Netherlands may reach 132 GW of solar by 2050

A new report from the Netherlands Organisation for Applied Scientific Research (TNO) shows the strong potential of photovoltaics in all scenarios for the country’s future energy mix. According to the Dutch experts, solar may reach between 55 GW and 132 GW by 2050.

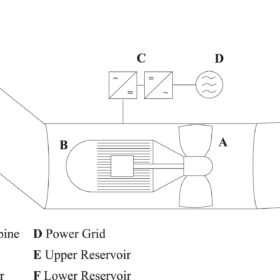

Pushing the boundaries of low-head pumped hydro storage

Two different studies have highlighted the potential and challenges of low-head pumped hydro storage (PHS), which has so far never been implemented in real projects. Different main areas were identified for future research and an interesting levelized cost of storage was indicated for certain project configurations.

Dutch energy provider Essent uses photovoltaics to produce hydrogen

The hydrogen generation facility will be initially powered by a photovoltaic plant, but Essent may also add wind power for periods when the sun is not shining. The energy company also plans to deploy some battery storage capacity at the plant for the temporary storage of the surplus of solar power that cannot be immediately converted into hydrogen or supplied back to the grid.