Photovoltaik-Institut Berlin (PI) acquires Solarbuyer

Through the merger with the U.S. company, the Photovoltaik-Institute (PI) wants to gain a foothold in the world’s second largest photovoltaic market, the United States.

Researchers develop ‘grass like’ light-scattering nano structure for solar glass

A team of scientists from the University of Pittsburgh have created a glass surface with an etched nano structure that allows for up to 95% light transmittance, and can also scatter the light entering the glass, so that more light reaches a solar cell beneath.

SoLayTec receives follow on order for ALD equipment

SoLayTec B.V, a subsidiary of U.S. based equipment provider Amtech Systems, has announced a follow-on order from an unnamed customer for its atomic layer deposition systems, to be used in PERC cell production.

ET Solar describes “reorganization” of its US module sales business

The Chinese PV maker and developer has made a statement regarding the bankruptcy of U.S. subsidiary ET Solar Inc.

IHS Markit: Global solar installations to pass 100 GW in 2018

Market analyst IHS Markit has issued its first forecast for 2018 installations. It expects the global market to surpass the 100 GW mark for the first time ever, hitting 108 GW.

US solar deployment hits lowest level in two years (w/ charts)

Slowing residential solar markets, higher prices for components and a push-back of project completions were the perfect storm in Q3, however the U.S. market managed to remain above 2 GW.

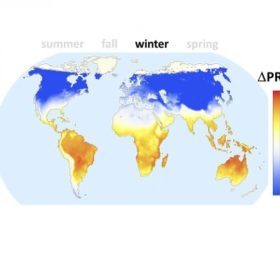

MIT researchers observe effects of climate on solar cell performance

Scientists from the Massachusetts Institute of Technology (MIT) have developed a tool to predict solar cell performance at any location worldwide. The tool utilizes a combination of global weather data gathered by satellite and cell performance data from two different locations.

US C&I storage rankings place Stem, Green Charge and AMS at top

In the increasingly competitive commercial-and-industrial storage market, IHS Markit expects the segment to grow 10-fold over the next five years – and ranks the companies that will lead the charge.

ET Solar Inc. files for bankruptcy

A U.S. module sales subsidiary of the Chinese PV module maker and developer has quietly filed for bankruptcy. Details are sparse, but the parent company’s U.S. project development and construction subsidiary has not been affected.

Fitch: Despite policy concerns, outlook stable for US renewables

The credit ratings agency says that despite moves by the Trump Administration, the increasing competitiveness and predictable output of renewable energy still makes it a good bet.