In search of the perfect polymer for PV backsheets, encapsulants

Scientists in Austria have examined the impact of different backsheet and encapsulant material combinations on module performance and degradation. This led them to develop a model to quantify the degradation rates of different materials, potentially helping manufacturers to identify better, longer-lasting materials for these vital module components.

Hanwha Solutions to set up TOPCon module production line, build EVA factory

Hanwha Solutions has unveiled a $548.8 million plan to enter the TOPCon module business and expand its EVA production capacity in South Korea.

Quanex releases new solar panel sealant

Texas-based Quanex’s new sealant helps to delay power losses over a PV module’s lifetime and extends useful lifetimes by locking out moisture.

EVA the next supply chain pinch point for solar

With polysilicon production capacity having been rapidly rolled out after last year’s shortages, China analyst Frank Haugwitz has suggested global manufacturing capability for the ethylene vinyl acetate used on PV panels could struggle to keep pace with what is expected to be another record year of demand for solar.

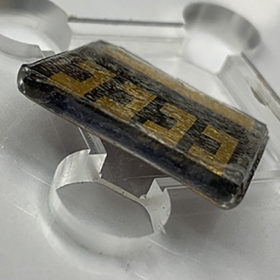

Lead absorbing encapsulant for perovskite solar cells

Scientists in the United States developed what they describe as a ‘scotch-tape like’ solution, which can absorb potential lead leakage from perovskite solar cells, preventing the toxic material from entering the environment. The tape, according to the scientists, can easily be integrated with existing encapsulation strategies, and was shown to absorb 99.9% of lead leaked from cells from that were severely damaged.

China’s emission-reduction action squeezes PV production

Industrial shutdowns and reduced factory production capacity levels indicate the companies producing the raw materials used by solar manufacturers are being afflicted by electricity consumption measures just as other sectors are. It is not clear whether the solar industry will be afforded any favors by Beijing, as analyst Frank Haugwitz explains.

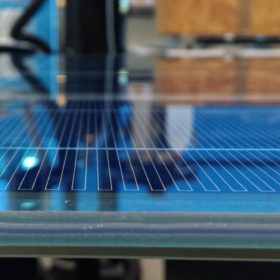

The weekend read: Bifacial drives PV encapsulant switch

Suppliers of encapsulant materials – plastic sheets that are heated to laminate together the components in PV module stacks – are rapidly expanding to keep pace with module manufacturing in Asia and other parts of the world. Ethylene-vinyl acetate (EVA) continues to dominate the market, but new developments in module technology are driving a slow shift to more costly polyolefins.

New process to recover PET and EVA from recycled solar panels

Researchers in China are proposing a new technique to recover polyethylene glycol terephthalate (PET) and ethylene-vinyl acetate (EVA) in solar panels at the end of their lifecycle. The two materials represent around 15% of the total material in a wasted solar cell, with a share of 10% for EVA and 5% for PET, respectively.

Raising the efficiency of polycrystalline cells with new luminescent EVA film

Chinese researchers have developed a pure EVA film, which they claim can enhance the conversion efficiency of conventional crystalline solar cells by around 0.50%. The film is able to convert UV light into strong visible light.

India slaps anti-dumping duties on solar EVA sheets

India’s Directorate General of Foreign Trade (DGTR) has concluded that duties ranging from $537 to $1,559/metric ton will be needed to offset the impact of imports of solar ethylene vinyl acetate (EVA) sheets from China, Malaysia, Saudi Arabia and Thailand. The harshest duty — $1,559/metric ton (MT) — has been imposed on sheets supplied by all Saudi manufacturers other than Saudi Specialized Products.