Inkjet printed formamidinium tin-lead perovskite cell with 10.26% efficiency

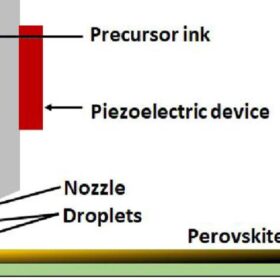

Researchers from Germany and India have demonstrated an inkjet printing method to fabricate formamidinium tin-lead perovskite solar cells, achieving 10.26% power conversion efficiency and a 1.25 eV energy bandgap.

KIT researchers develop18.2%-efficient perovskite solar cell via scalable inkjet process

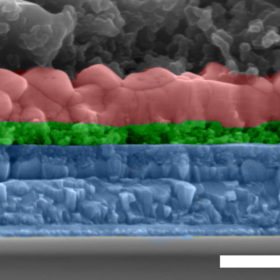

Researchers at Karlsruhe Institute of Technology (KIT) have developed a scalable two-step evaporation and inkjet process for perovskite thin-film solar cells. The new technique reportedly enables to build champion cells with the same efficiencies as those made with the spin coating process.

Japanese scientists trial printing on perovskite

Researchers from three Japanese universities have developed a process based on inkjet printing they say could reduce the cost of perovskite solar cell production. The group fabricated small cells with efficiencies as high as 13.19%, a figure they claim is promising enough to offer the possibility of scaling up to commercial production.

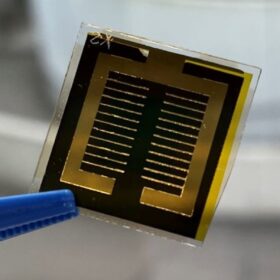

Panasonic claims 16.09% efficiency for lightweight perovskite solar module

The device has an area of 802cm² and thickness of 2mm. The manufacturer claims it improved module performance through an inkjet coating method and a reduction in weight by using thin glass substrates.