The sun rises on the bifacial module market

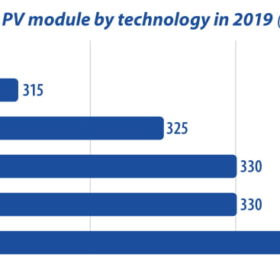

With market penetration exceeding expectations in 2018, bifacial technology is set to account for one third of global solar module production by 2022, writes Edurne Zoco, Research Director at IHS Markit. Bifacial and half-cell technologies are rapidly gaining momentum due to their improvements in power output, along with their low implementation barriers and minimal capex requirements

Innovation and uncertainty mark SNEC 2019

There was plenty of innovation on display at this year’s SNEC, which closed yesterday afternoon at the Shanghai New International Expo Center. The three-day exhibition ran from Tuesday to Thursday, was well attended and still ranks as the world’s largest solar energy trade show.

UK scientists observe LID in action

A team of researchers from Manchester University claims to have identified the dominant process causing light-induced degradation in silicon solar cells. The process, termed “trap-assisted auger recombination”, arises from a defect in the bulk of the silicon material which lies dormant until exposed to sunlight.

AE Solar to open 500 MW European module factory in Georgia

The German panel maker said the new factory, which will add to its 525 MW facility in China, will expand its production capacity to 1 GW. With plans in the pipeline to enter the PV project business, that figure could rise to 2 GW by the end of next year.

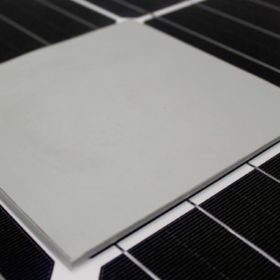

Sharp launches three new mono-PERC modules with 19.1% efficiency

Sharp has released three new high-efficiency mono-PERC solar panels. Ranging from 300 W to 370 W, the five-busbar modules are designed for use in a range of applications, from residential PV projects to large commercial installations.

Phono Solar: Module factories in the US and South America on the horizon

pv magazine recently caught up with Aaron Wu, executive vice president of Phono Solar Technology, the Nanjing-based PV manufacturer. Phono Solar is a bankable supplier, having achieved top tier status in 2014 and being part of SUMEC Group Corp., a diversified industrial group with over RMB 80 billion ($11.87 billion) in turnover in 2018.

Longi’s 5 GW high-efficiency mono PERC factory will be at full capacity ‘soon’

The Chinese panel maker is already producing bifacial half cut modules at its new Anhui fab after the completion of an initial 2.5 GW phase of operations. And the company president confirmed Longi is on track for 45 GW of mono wafer and ingot production capacity next year.

Smart Energy Week in Tokyo: Self-consumption, storage and a plentiful pipeline for now

Though we’re unlikely to see a return to the days of double-figure GW annual installation levels, Japan will stay at the top table of solar. Last week, pv magazine visited PV Expo Japan, part of Tokyo’s World Smart Energy Week, and found plenty of market developments to discuss, along with healthy interest from major players.

1366 Technologies and Hanwha Q Cells to open wafer factory in Malaysia

The U.S. wafer maker and the Korean module manufacturer expect to ramp the Malaysian factory no later than September. The fab is next to Hanwha’s existing cell and module facilities and 1366 Technologies plans to produce its Direct Wafers on a gigawatt scale for less than $0.20 per piece.

SERIS aims for 24% efficiency for mono PERC cell

The Singapore research institute will cooperate with China’s Ruxing Technology to increase the efficiency of its monoPoly™ technology. Through this cooperation, SERIS believes its solar cell efficiency could be raised to 24%, and module power beyond 345 W.