German solar module manufacturer AE Solar GmbH will open its new panel manufacturing facility in Kutaisi, Georgia this month, business development manager Shokhrukh Baratov told pv magazine.

The factory is being equipped with fully automated production lines provided mainly by an undisclosed equipment supplier, and will have an annual capacity of 500 MW. “On April 14, we start [the] debugging process, meaning the start of manufacturing activities at low capacity,” Baratov said. “[The] debugging process will take two to three weeks and after, we can start at full capacity.”

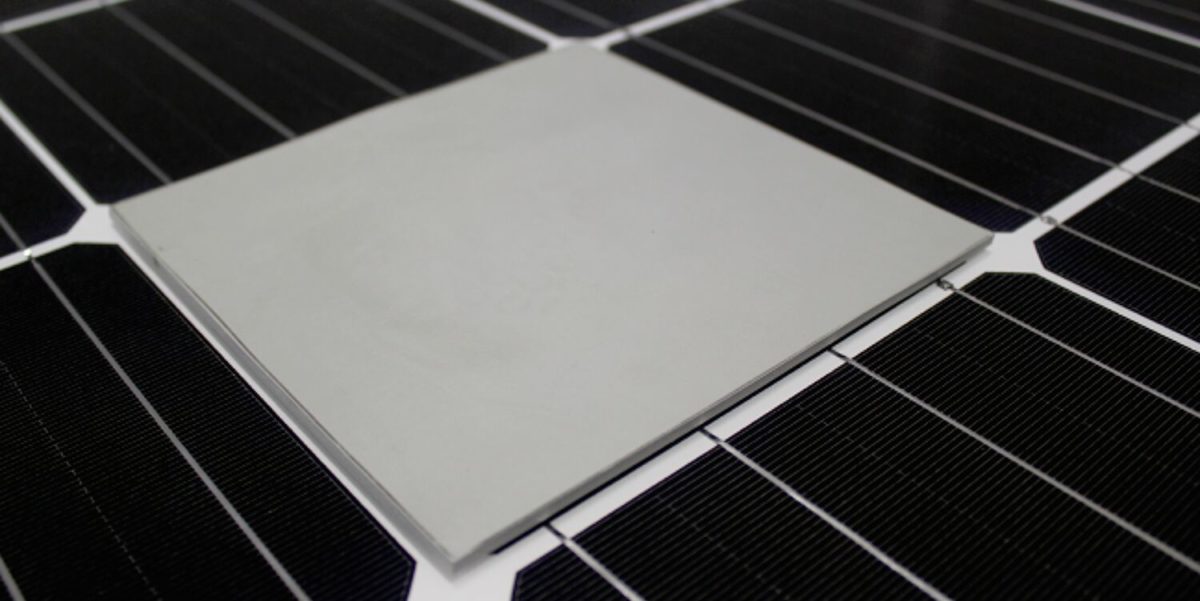

The 16,000 m² facility will make a range of poly and mono modules including PERC panels and will include non-Chinese bill of materials products for the U.S. and EU markets, Baratov added. “We will use in our product line transparent back-sheets, bifacial cells and our Smart Shading Resistant Hot-Spot Free technology,” he said.

Strategic location

Baratov said Georgia is an ideal location for module manufacturing as the country has free trade agreements with the EU, India and China as well as duty preferences with the USA, Mexico, the Commonwealth of Independent States post-Soviet nations, Turkey, Japan and others.

“The Poti seaport on the eastern Black Sea coast is near our factory and we have land access by trucks to many countries around Georgia,” Baratov said, adding the fab is in the Kutaisi free industrial zone, ensuring AE Solar will be exempted from import and export duties and taxes, as well as other taxes and VAT, for example on electricity. “Labor and electricity costs in Gergia are low,” Baratov added.

Capacity expansion

Popular content

The factory will add to AE Solar’s 525 MW manufacturing facility in Hongze, China, which has been running since 2009, raising the company’s annual production capacity to more than 1 GW. Even that may not be enough to keep up with demand, Baratov said, as AE Solar is planning to enter solar project development.

The business development manager told pv magazine the company’s total production capacity may rise to 2 GW by the end of next year.

AE Smart Shading Resistant Hot-Spot Free panels were chosen by an independent jury as pv magazine’s top innovation highlight in June. The modules consist of three substrings with three bypass diodes, each of which protects an entire substring.

In a study for AE Solar, Germany’s Fraunhofer CSP certified if a cell is shaded in an AE panel of that nature, only 3% of power may be lost – in standard modules the shadowing of one cell could result in power loss of up to 30%.

The string current in the AE module passes across the bypass diode and the remaining 20 cells in the string can continue to produce current. “The new AE solar module loses only 20% of its rated output,” stated the Fraunhofer report, while conventional modules were said to be susceptible to lose all of it.

The innovation also has a safety aspect because shaded cells heat up and develop hotspots when not protected by a bypass diode. While ‘hotspot-free’ is not entirely accurate – given such defects can occur because of problems in the wafer – AE’s technology significantly reduces the likelihood of such problems.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.