JA Solar unveils 415 W solar module with 21.3% efficiency

The module can be used for residential and commercial PV projects. It is available in five versions with power outputs claimed by the company of 390-415 W and reported efficiencies of 20.0-21.3%.

US government wants to cut solar costs by 60% in 10 years

The US Energy Department set a goal of achieving 2 cents/kWh by 2030, and announced an initial $128 million in funding to support technology development.

Cooling PV panels with HVAC system exhaust

A French-Lebanese research group has proposed a way to cool down PV modules by using air exhausted from heating, ventilation, and air conditioning (HVAC) systems. They showed that array performance improves when the cooling load rises.

Polyelectrolyte-based inverted perovskite solar cell with 20.29% efficiency

Taiwanese researchers have added bathocuproine (BCP) molecules to three different kinds of solvents used in perovskite cells and have ascertained how this combination increases the carrier mobility and passivates the electron-poor defects. Furthermore, they utilized a polyelectrolyte (P3CT-Na) thin film as hole transporting material instead of commonly-used thin films based on PEDOT:PSS.

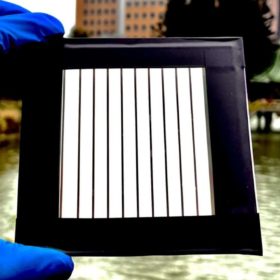

New photonic material for self-aligning solar cells

US scientists have made light-tracking, three-junction tandem PV cells with an active area of 650 × 650 square micrometers. They are based on indium gallium phosphide, gallium arsenide, and indium gallium arsenide antimony nitride and use photonic crystal film for maximum efficiency.

Chinese PV Industry Brief: Another factory under construction

Talesun has begun work on its 5 GW factory in Siyang county, Jiangsu province and China’s second-largest grid operator, China Southern Power Grid, has announced around 200 GW of renewable energy capacity will be deployed on its service area over the next 10 years.

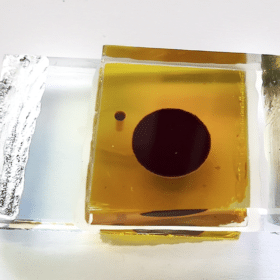

Grätzel solar cell with 13.5% efficiency, high open-circuit voltage

Scientists from Switzerland fabricated a dye-sensitized solar cell with a new tailored organic photo-sensitizer coded MS5 and a copper (II/I) electrolyte. A device solely sensitized with MS5 showed an open-circuit voltage of 1.24 V, which the researchers said is a record value among copper-based Grätzel cells.

New manufacturing tech for 16.06%-efficient mini perovskite solar modules

A US-Taiwanese research group has created a new spin coating method which they claim can be applied in the mass production of mini perovskite panels. The scientists used sulfolane as an additive in the perovskite precursor to convert the perovskite phase via a new reaction route. They demonstrated a mini-module with a power conversion efficiency of 16.06% and an active area of 36.6 cm2.

Chinese PV Industry Brief: Work begins on 50 GW wafer factory, Shanghai Electric bets on green hydrogen

Tianjin Zhonghuan Semiconductor began building its new wafer manufacturing facility in the Ningxia Hui autonomous region. Shanghai Electric is setting up a hydrogen research center with the Dalian Institute of Chemical Physics of the Chinese Academy of Sciences.

New delamination technique for PV module recycling

French research institute CEA-Liten has created a technique that consists of using a diamond wire to cut through the photovoltaic cells, separating the module’s glass front face from the polymer-based backsheet. The process is claimed to be low-polluting and low-energy.