A group of scientists from the US Department of Energy's Los Alamos National Laboratory and the National Taiwan University (NTU) has developed a new manufacturing process for mini perovskite solar modules that is claimed to overcome key bottlenecks in large-scale production.

“The levelized cost of electricity (LOCE) from a solar module includes power conversion efficiency, module lifetime and the production cost,” research co-author, Leeyih Wang, told pv magazine. “We think our study has provided a solution for all three factors, as the high-efficiency demonstration and greatly extended lifetime from our module can contribute to lower the LCOE.”

The manufacturing technique is based on a one-step spin coating method using sulfolane, which is a dipolar aprotic industrial solvent, commonly used in gas production and oil refining. “We introduce sulfolane as an additive in the perovskite precursor to convert the perovskite phase via a new reaction route, providing a large degree of flexibility to process crystalline perovskite layers with high uniformity on a large scale,” the scientists explained.

Adding sulfolane to the perovskite precursor, according to the researchers, extends the processing window from nine seconds to 90 seconds, forming highly crystalline, compact layers over a large area while being less dependent on the processing conditions. “Broadening the processing window in the antisolvent route is essential in transferring the process to industrial production for perovskite module fabrication,” co-author Hsinhan Tsai told pv magazine. “It allows the flexibility in up-scale process development without sacrificing the device performance.” Large-scale production can also benefit from the widened time window, allowing greater tolerance of manufacturing errors and environmental variations, he added.

Popular content

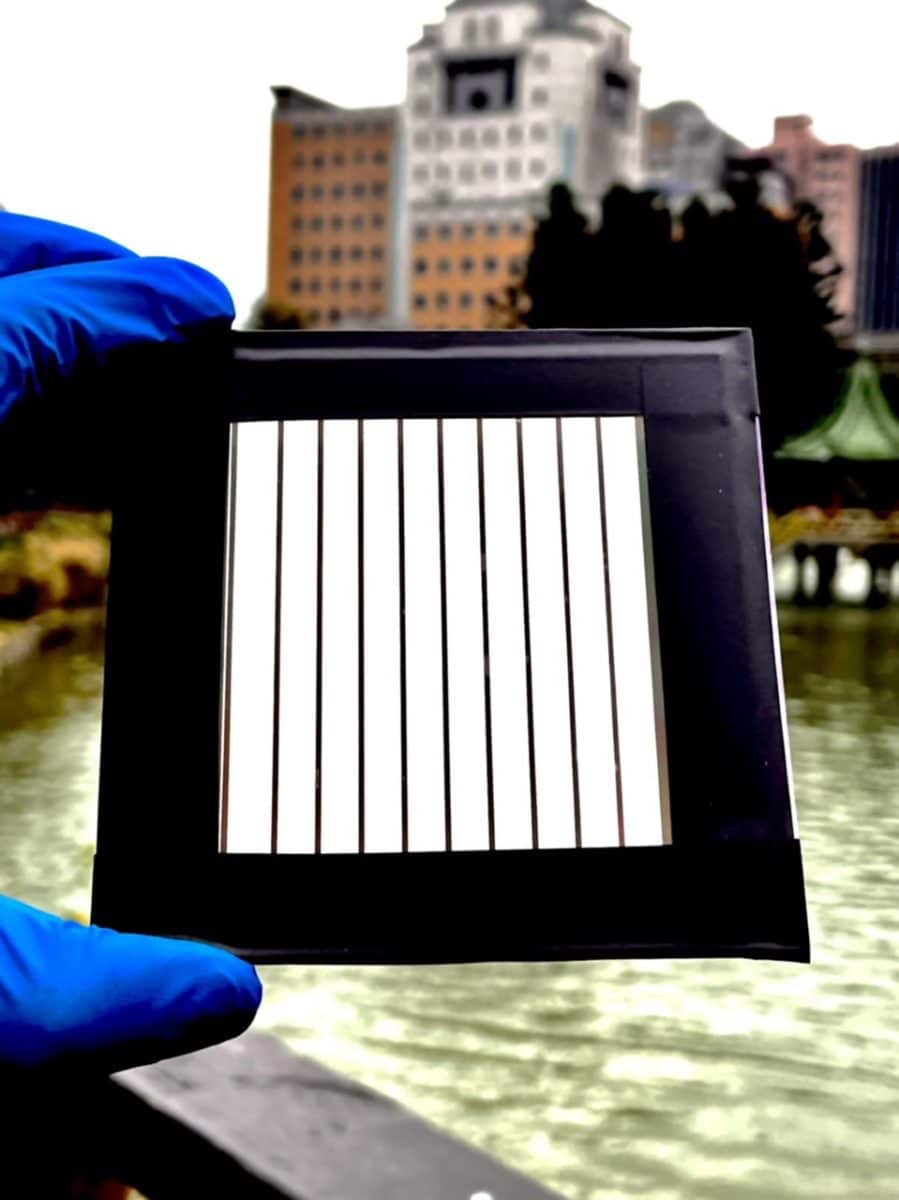

Through the proposed manufacturing technique, the US-Taiwanese group was able to demonstrate a mini-module with a power conversion efficiency of 16.06% and an active area of 36.6 cm2. “More importantly, this is a method to greatly improve the production yield that can thus support high-rate production, which is an important factor for lowering the fabrication cost,” said researcher Wanyi Nie. The team was also able to fabricate a mini module with an active area of 36.6 cm2 and an efficiency of 17.58%.

The academics said they have also successfully tested their method by blading as well and believe the precursor can be adapted to industrial-scale fabrication tools like a roll-to-roll process. “We currently only processed at the laboratory level,” said co-aouthor Hsin-Hsiang Huang. “The production line evaluation on perovskite solar cells via this new reaction route is ongoing.” He believes that more reproducible perovskite layers with high uniformities on a large scale can be realized.

The production process is described in the paper “A simple one-step method with wide processing window for high-quality perovskite mini-module fabrication,” published in Joule.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

6 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.