Pure sulfide CIGS solar cell with 15.2% efficiency

The device was built by an international research team. The cell features a buffer layer based on zinc sulfide oxide and a low copper absorber. The cell showed an open-circuit voltage of 920 mV. And though a different material from the widely commercialized CIG selenide PV thin films, the researchers claim similar processes could be used in its large-scale manufacturing.

New process to recycle silicon, silver and glass from end-of-life PV panels

A €4.8 million EU-funded research project is aiming to develop a process that allows recovering all components of a photovoltaic module.

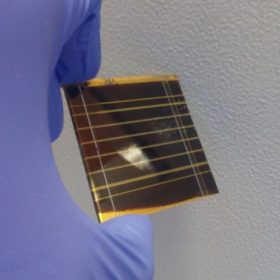

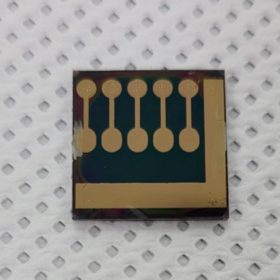

Perovskite solar panel with 16.1% efficiency via ambient air blade-coating

The panel, fabricated by scientists in Italy, is composed of five series-connected cells, each with an area of 2.01 cm² and has an aperture area of 11 cm². It showed a power conversion efficiency of 16.1%, an open-circuit voltage of 5.59 V, a short-circuit current of 37 mA, and a fill factor of 72.5%.

Solar module cooling technique based on multiple phase-change materials

Academics have utilized three PCMs, known as RT26, RT35, and RT42, and decided to pack them ascendingly depending on their melting points and heat-flow direction. The system is claimed to allow lower melting rates and longer thermal management of the modules.

Chinese PV Industry Brief: Huawei launches new unit for renewables and electric vehicles

The technology company and inverter maker has created a new unit to operate in the renewables and e-mobility sectors. Elsewhere, China’s largest e-commerce company, JD.Com, has signed an agreement with the world’s biggest wind company, GoldWind, to establish a renewables joint venture.

Simplifying solar cell deposition

Scientists in Germany have developed a new process for deposition of silicon dioxide layers during cell production. Without the need for high pressure, flammable gases, or vacuum conditions, the process could lead to cost reductions for cell manufacturers, provided it can be developed and applied in a large-scale production setting.

Perovskite solar cell with 19.1% efficiency via CO2 doping

Thanks to a carbon dioxide doping technique, the solar cell interlayers exhibited conductivity around five times higher than that of a perovskite cell based on interlayers doped with oxygen. The device also showed an open-circuit voltage of 1.14 V, a short-circuit current density of 21.2 mA cm2 and a fill factor of 0.79.

Smart sticker for smart solar modules

The sticker is based on a blockchain technology developed by German start-up Authentic Network. Meyer Burger uses the application for the photovoltaic modules it produces in its new factory that opened in Freiberg at the end of May.

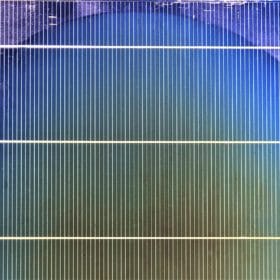

PV modules degrade less in Nordic climates

Norwegian researchers have used a year-on-year approach, considering the combined effect of temperature, humidity, and ultraviolet irradiation, to assess the degradation rate of polycrystalline modules with a temperature coefficient of -0.43%, mounted with an approximately 10-degree tilt, and located in eastern Norway. They found that these modules degrade in the range in the range of 0.1-0.19% per year, which is 0.4% less than panels operating in other climates.

Chinese court upholds laminator patent

German manufacturer Robert Bürkle GmbH has obtained a first instance judgement preventing a rival company from producing equipment that infringes on its patents. The decision of the Intermediate Peoples Court in China is not yet final, and the rival company has already filed a complaint against the ruling.