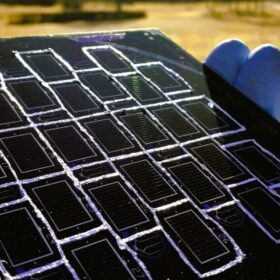

Global cadmium telluride solar module manufacturing capacity could reach 100 GW by 2030

In a perspective paper in Joule, a group of U.S. researchers described technology and supply chain efforts required to reach worldwide annual cadmium telluride (CdTe) solar PV capacity of 100 GW by 2030.

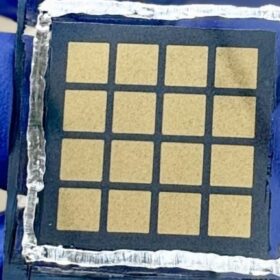

Korean scientists boost performance of tin monosulfide cells with new post-treatment

Researchers in South Korea improved the performance of tin monosulfide (SnS) solar cells with a potassium fluoride-assisted post-treatment and a vapor transport deposition process. The treated solar cells had a power conversion efficiency of 4.10% and reduced recombination sites, compared to 3.42% for untreated devices.

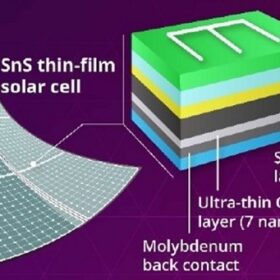

Korean researchers build tin monosulfide solar cell with 4.81% efficiency

The efficieny result represents one of the best performances ever achieved for this kind of thin-film solar cell to date. The device was fabricated with a rear contact interface that reportedly enhances charge transport.

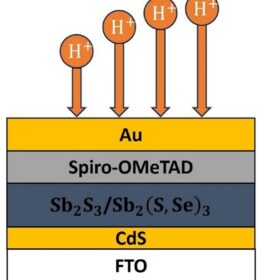

New research shows antimony chalcogenide solar cells are suitable for space use

Researchers in the US tested the degradation of antimony chalcogenide solar cells exposed to proton radiation. The result indicated a robust tolerance and potential for use in space.

U.S. scientists build antimony sulfide solar cell with 7.69% efficiency

Researchers at University of Toledo produced antimony sulfide (Sb2S3) thin film solar cells with 7.69% power conversion efficiency after determining optimal hydrothermal deposition, post annealing, and light soaking conditions. Stability tests showed more than 95% of initial efficiency after ten months.

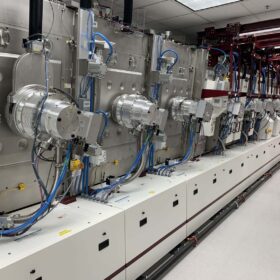

Thin-film solar patents, manufacturing equipment listed for sale

A cancelled factory led to the sale. The solar cells produced by the equipment are “game-changing tech at liquidation values,” said the seller.

China imposes export controls on critical minerals for thin-film PV

China has announced new export restrictions on materials essential for the thin-film solar industry, including critical minerals such as tungsten, tellurium, and indium.

First Solar’s unit, Uppsala University present CIGS solar cell with world record efficiency of 23.64%

The new solar cell achieved a maximum power conversion efficiency of 23.75% and a certified efficiency of 23.64%, thus beating the previous world record of 23.35% achieved in 2019 by Japan’s Solar Frontier. The result was confirmed by the Fraunhofer ISE.

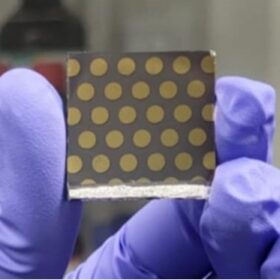

Cadmium telluride solar cell based on indium gallium oxide emitter achieves 17.2%

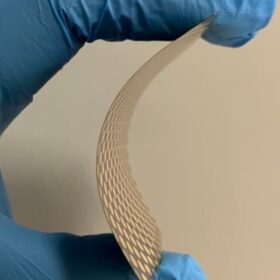

Developed by the University of Toledo, the cell achived the highest efficiency ever reported for flexible cadmium telluride solar cells to date. The device reached an open-circuit voltage of 861 mV, a short-circuit density of 27.8 mA/cm2, and a fill factor of 71.7%.

Thin-film solar is the future of agrivoltaics

In contrast with traditional panels, thin-film solar modules are much more adaptable to these agricultural situations, thanks to their flexible, lightweight design.