Chinese PV Industry Brief: New supply deal for Daqo plus more cell and PV glass production capacity

Chinese polysilicon manufacturer Daqo has secured a long-term supply agreement with PV equipment provider and monocrystalline wafer manufacturer Wuxi Shangji Automation, Shanxi Coal International Energy Group has unveiled a plan to set up a 10 GW heterojunction solar cell production fab and Longi has held its wafer prices.

Manufacturing industry seeks unity on wafer size

Seven solar manufacturers, including tier-1 players, have signed up to a joint initiative aiming to establish a new standard size for silicon wafers at 182mm x 182mm. Conspicuously absent from the initiative is China’s Zhonghuan Semiconductor, which last year introduced a 210mm solar wafer, the largest seen in the industry so far.

Solar grade silicon production comes back to Spain

Rivas-Vaciamadrid-based company Aurinka is planning to start UMG silicon manufacturing in Puertollano, Castile-La Mancha, this year. The company says its patented low-carbon production process offers low enough manufacturing costs to compete with Asian rivals.

Coronavirus to have limited impact on Chinese polysilicon industry

Analyst Johannes Bernreuter says most of China’s polysilicon production capacity is in regions away from the center of the coronavirus outbreak. He added, however, 27% of the nation’s 510,000-ton annual polysilicon capacity could be affected.

1366 Technologies adds $18m in pursuit of cheaper silicon solar cells

The company’s technology falls into the ‘kerfless’ wafer category: Instead of sawing silicon ingots into wafers, a time-consuming and wasteful process, 1366’s approach forms wafers directly, using molten silicon.

Upgrades needed to process larger wafers, says VDMA

In an update to its International Technology Roadmap for Photovoltaics, German engineering association the VDMA notes standardization of wafer size is a topic of great interest to the country’s PV equipment manufacturers, and modifications to lines will be needed to process wafer pieces larger that 161mm.

The weekend read: Size matters

The latest development on the module front sees manufacturers adopting larger wafer sizes in order to reach the industry’s raised expectations for power output. Older “M2” wafers have been the standard in recent years but now appear to be on the way out. Several theories about optimal size are gaining ground, but the future direction of the standard is still far from clear.

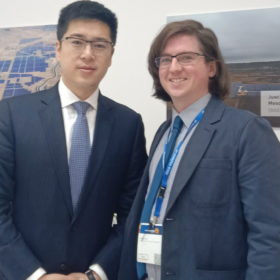

Well it’s Swan for the money…

This year JinkoSolar launched its bifacial Swan module, one of the first to feature a transparent Tedlar backsheet made by DuPont. pv magazine had the chance to catch up with Gener Miao, JinkoSolar VP for global sales and marketing for an update on the module’s innovations, and on how the company sees solar markets this year.

Zhonghuan Semiconductor and GCL-Poly to expand production of mono wafers by 25 GW

The joint venture of the two giant manufacturers will expand its capacity from around 30 GW currently to 55 GW over the next three years. This plan is expected to require an overall investment of $1.34 billion.

Jinko announces 5 GW wafer factory and 10.7 GW of module supply deals

The new manufacturing facility will be located in Leshan, in China’s Sichuan province and will produce monocrystalline wafers. It will raise the group’s wafer capacity to around 11.5 GW. Meanwhile, large supply deals are said to have come from markets including Vietnam, Mexico and Spain.