Researchers at Turkey’s Firat University have tested how temperature changes affect the durability of solar glass under different operating conditions.

The scientists said they used two types of solar glass – referred to as A and B types – both 4mm thick and featuring light transmittance of 91.8% and 91%, respectively. Both materials were certified as the highest quality P1 grade. Light transmittance is a value indicating how much incoming light passes through the solar glass. That value, as well as that of the absorbance and reflectance properties of the two materials, were analyzed using a UV-3600 Plus Spectrometer.

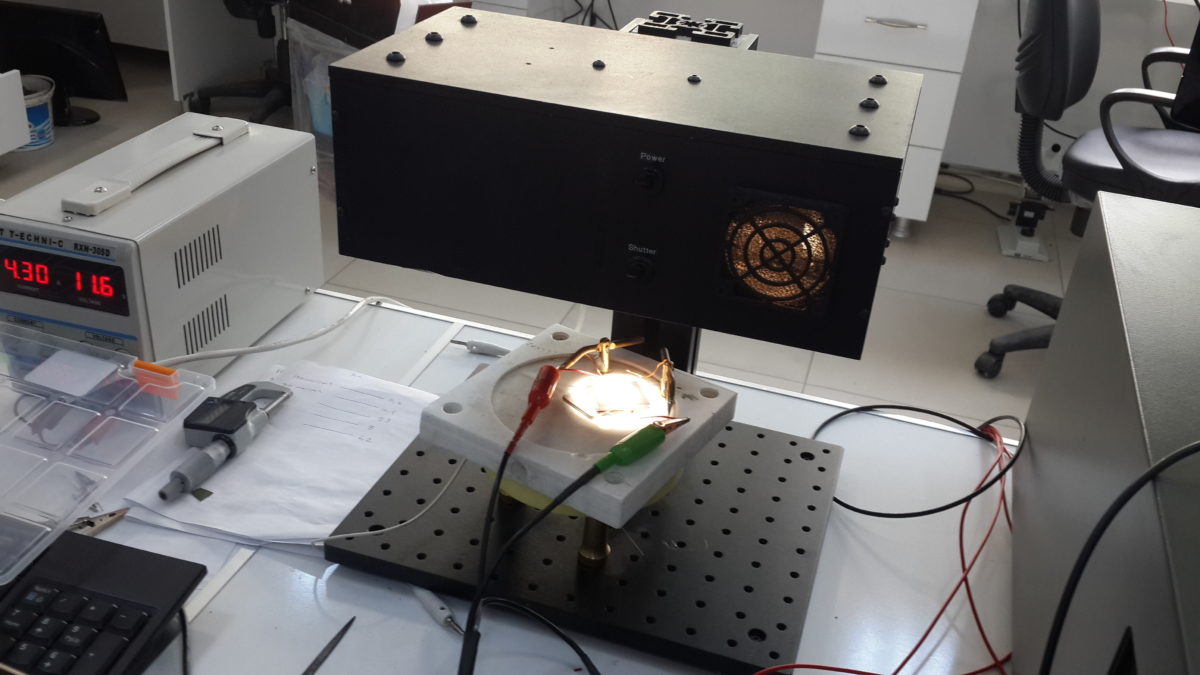

Image: Firat University

The researchers said only the surface shape of the materials differed – all other properties, such as iron ratio, thickness and thickness tolerance, density, surface treatment, temper information and temperature resistance were similar.

The two types of glass were submerged in liquid nitrogen with the glass temperature reduced to -50 degrees Celsius and were then abruptly dipped in hot water of 50 degrees Celsius. “Temperature ranges are considered as cold after [minus] 50 degrees Celsius and hot from 20-70 degrees Celsius,” the scientists said.

Exergy efficiency

After that process, the materials were placed on a 2.05% efficient solar cell and measurements were made with a solar simulator. The researchers said the experiment enabled them to verify the exergy efficiency values of the glass tested varied from 0.66-1.49%, depending on radiation value. Exergy efficiency is the ratio of the thermal efficiency of a given system to an idealized or reversible version.

“In the measurement results for type A samples, the exergy efficiency values vary between 0.67% and 1.42%, according to the solar radiation,” the researchers wrote in the paper Determination of the effects of temperature changes on solar glass used in photovoltaic modules, published in Renewable Energy and on the ScienceDirect website. “The values of exergy efficiency for the samples B vary from 0.66% to 1.49%, according to solar radiation.”

Popular content

The scientists reported the solar cell saw conversion efficiency vary 0.66-1.41% under glass type A, and 0.63-1.47% under glass type B. “The most noticeable difference is observed in the power conversion efficiency values obtained from both types of solar glass in which temperature differences of -50 degrees Celsius and 50 degrees Celsius, 30 degrees Celsius [and] 40 degrees Celsius are applied,” the researchers wrote.

Analyzing micro-cracks

Image: Firat University

To understand the values, the research team analyzed the possible presence of micro-cracks on the materials after the two glasses reached the critical temperature range.

The Turkish team ascertained reduction in both exergy and energy efficiencies were attributable to a large number of micro-cracks and deformations on the glass surfaces, which were responsible for considerably affecting the absorbance, transmittance and reflectance properties of the materials.

“Between different wavelength densities, the reflectance ratios of the samples used in the experimental study range from 2 to 8% for the sample A and from 6 to 14% for the sample B,” said the Firat University team.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.