From pv magazine 04/2020

There is no shortage of challenges to scaling up perovskite technologies from the laboratory to commercial production. Among these is flash testing and cell characterization: A new technology will require new techniques to measure, and new standards to base these measurements on. “In some ways everyone who is working on perovskites is ahead of the compliance side of testing and certification. Standards and protocols have not really caught up with what will be a new technology,” says Chris Case, CTO of Oxford PV, which is currently installing equipment for a 250 MW perovskite/silicon tandem cell manufacturing line in northern Germany.

And for perovskites and tandem cells that incorporate them, it seems a new approach to inline testing may be required. “There are some fundamental differences in our perovskite material’s characteristics, including how it responds to testing and how it will respond to some of the certifications,” says Case.

Maximum power point

In the research and development setting, cells are measured over a period of minutes. Researchers track a cell’s maximum power point (MPP) and ensure that it has stabilized before taking a measurement, rather than the standard IV sweep that is performed for silicon PV measurements.

“Typically, perovskites might show some hysteresis, which means that the efficiency is slightly different whether you scan from low to high or high to low voltage,” explains Jan Goldschmidt, head of the Novel Solar Cell Concepts Group at Fraunhofer Institute for Solar Energy Systems. “So then you estimate from the IV curve where your MPP will be, then you set the voltage at the MPP and you vary it a little bit to track the MPP. Then you record the output of your solar cell in the time. This is what we call a stabilized measurement.”

This method has become an unofficial standard among universities and research institutes for measuring perovskite and tandem cell efficiencies and is a lot more time consuming than the required measurements for a silicon solar cell. “We characterize perovskite cells and tandems by JV scans with different scan speeds and scan directions followed by MPP tracks over several minutes,” says Steve Albrecht, whose group at Helmholtz-Zentrum Berlin currently holds the efficiency record for a perovskite/silicon tandem cell. “For typical silicon cells, no hysteresis is measured, and thus quick scans will usually provide the correct information of the parameters.”

Light spectrum

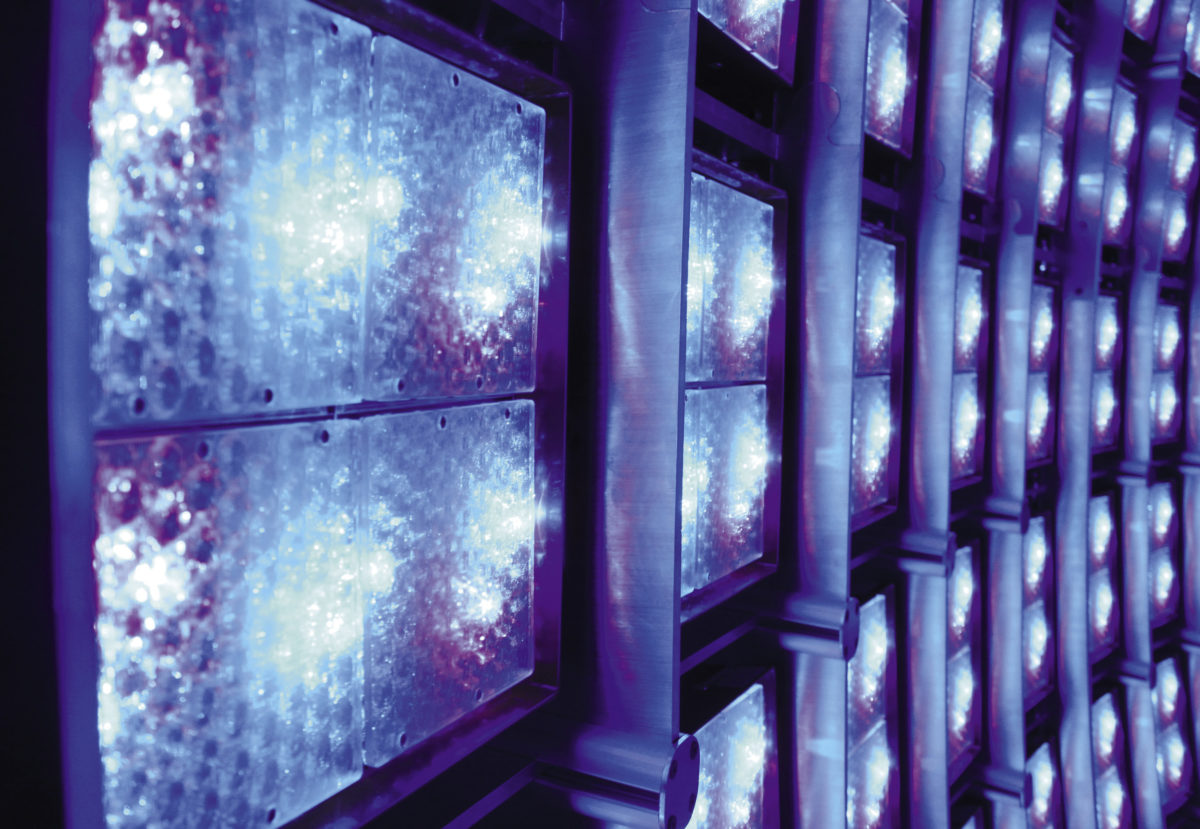

A highly accurate light spectrum is another key consideration. This is a starting point for any solar simulator, but for testing tandem cells, this – as well as the ability to fine-tune that spectrum – becomes even more crucial. “The current that flows through both cells has to be identical. If you have two cells in tandem, if you don’t have perfect spectral match then one cell can limit the other,” says Torsten Brammer, CEO at German flashing-system supplier Wavelabs. “It’s also helpful if you can adapt the spectrum to see which one is actually limiting – add more blue or more red to find out whether the top or the bottom cell is limiting. I think this would also be helpful in production.”

One second or less

Developing a test that can be applied to mass production is another question entirely, though. And it’s one that will have to be answered for perovskites to make the jump into commercial production. “A precise power rating measurement procedure is one key topic to bringing a new technology to the market. Margins in PV projects are small and project developers need low uncertainties to calculate electricity prices,” says Klaus Ramspeck, R&D director at testing equipment manufacturer h.a.l.m. elektronik GmbH. “Perovskites are a very young technology. The necessity of a precise measurement and high throughput production to compete on the market is unquestionable.”

To keep up with throughputs of 5,000 pieces per hour or higher, testing and characterization on production lines needs to be carried out at a much faster pace. Manufacturers expect to be able to flash their cells at a total cycle time of one second per cell, with many setting targets of 0.8 seconds or even faster, as throughput elsewhere in the cell production process continues to rise.

And while the challenge of developing a reliable method to test perovskite and tandem devices is certainly on the radar of flashing equipment suppliers, no definite solution has emerged so far. “This is an open research question,” says Goldschmidt. “You really need to look at the internal dynamics, how it reacts to a very fast flash. It’s challenging but I’m pretty sure it can be done.”

A possible solution would be to expose the cells to light before they enter the solar simulator, initiating the stabilization process before the flash used in the measurement. This would come with its own set of problems, however. “Some are thinking of exposing the cell to light before,” says Brammer. “But then you also have heating of the solar cell. You want the cell to be 25 degrees or at least in that range.”

Commercial volumes

Most laboratories work only with small numbers of cells, and with experimental fabrication procedures, meaning a high degree of variance between cells. There is a fair assumption that any perovskite or tandem cell that makes it as far as mass production would have fewer defects, limiting the initial instability under light exposure and making the cell easier to characterize. This would allow manufacturers to take advantage of existing data to speed up their inline testing procedures.

“Lets assume you have a production line of perovskite cells: They won’t differ so much from each batch to the next one,” explains Goldschmidt. “For some of them you can make the slower stabilized measurement and compare these results to what you get with a short flash. And you can fine tune your flash characteristics, the time constant, intensity etc. Once you get results, you can map this on what you know in the stabilized test to use it on a production line.”

For the most part, equipment suppliers are beginning to take a serious interest in perovskite and tandem cell measurement, as they are now working closely with laboratories to study the material’s behavior inside a solar simulator. But finding a clear solution takes time. Like many in the PV industry, most see perovskite as a possible mass production technology a few years down the line. “So far, getting real devices to test measurement strategies proves a more complicated task then one would expect if mass production is just ahead,” says h.a.l.m’s Ramspeck. “We are investigating this topic and can assure you that we are going to accompany the path of this young technology to marketability.”

Ahead of the curve

For those already working to commercialize perovskite tandem cells, there’s no time like the present. Oxford PV says it has a solution planned for inline testing of its tandem cells, and has suppliers in mind for this equipment.

The production line will flash test the silicon cells separately at the end of their production, and then the complete device will be flashed again once the perovskite cell is integrated on top of the silicon cell. And the company will take an approach similar to that described by Fraunhofer ISE’s Goldschmidt – using a flash duration of less than one second and supplementing this with data from fuller characterizations. “What you have to achieve in this test is to make sure that your product effectively meets the requirements. It doesn’t necessarily mean that the measurement you make is an absolutely correct measurement,” explains Case. “As long as somewhere off the production line if I need to pull out a sample, every 10,000 cells or so, and do a full characterization to make sure everything is online, I can do that.”

Case goes on to state that the International Electrotechnical Commission (IEC), the body responsible for publishing testing standards for PV devices, currently has a report that summarizes possible changes to testing protocols that may be needed for emerging cell technologies such as perovskites or organic PV.

“We work on those committees and contribute to that activity, so we are looking forward to those standards catching up to the technology, says Case. “The IEC ratification process takes time but if changes are required to the current protocol, we will be ready.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

While we are on the subject of PV testing, is there any progress towards a standard for measuring off-axis performance? This is after all the typical case, and in a fixed-axis use light only only strikes orthogonally for a few minutes once a year.