While organic PV has long lagged behind silicon and other thin-film technologies, the potential for flexible and ultra-lightweight devices has led to some interesting niche applications in devices with low power requirements, such as wireless sensors and medical devices.

Studies have also shown that the availability of such niche markets for small scale devices can also accelerate the development of new technologies, providing the opportunity for researchers to gain experience with a material in a commercial production setting, without the considerable financial cost of developing pilot production lines that are unlikely to be profitable.

Scientists at King Abdullah University of Science and Technology (KAUST) looked at the opportunity for organic PV to provide power to medical sensing devices, building on previous research that demonstrated a glucose sensor that could be used by diabetes patients to monitor blood sugar without the need for any needles or blood samples.

“The tremendous developments in electronic skin for robots, sensors for flying devices and biosensors to detect illness are all limited in terms of energy sources,” says KAUST postdoc scientist Eloïse Bihar. “Rather than bulky batteries or a connection to an electrical grid, we thought of using lightweight, ultrathin organic solar cells to harvest energy from light, whether indoors or outdoors.”

Inkjet printing record

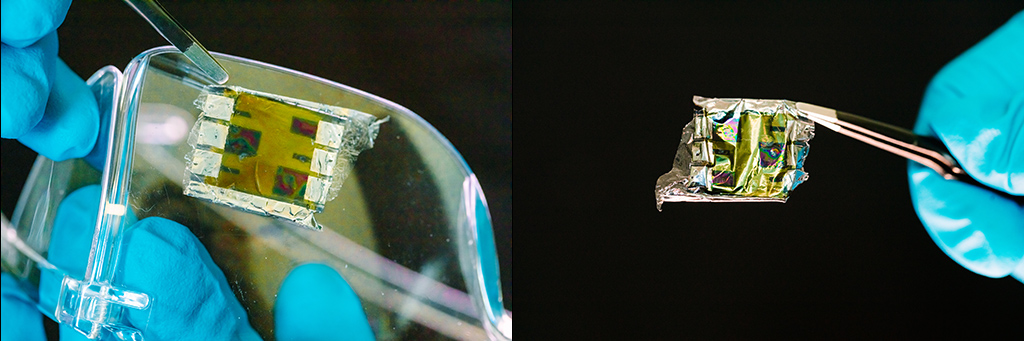

Using inkjet printing, the group was able to deposit all layers of the device using inkjet printing. The cells achieved 4.73% efficiency deposited onto a glass (a world record for a fully inkjet printed device) and 3.6% on a flexible substrate. The group notes that this also places performances achieved through inkjet printing on a par with other industrial processes such as spin and blade coating.

Popular content

“Inkjet printing is a science on its own,” says Daniel Corzo, a KAUST Ph.D student who worked on the paper. “The intermolecular forces within the cartridge and the ink need to be overcome to eject very fine droplets from the very small nozzle. Solvents also play an important role once the ink is deposited because the drying behavior affects the film quality.”

Key to the achievement, according to KAUST was the use of PEDOT:PSS as an organic electrode material, replacing the more commonly used indium tin oxide. Two different formulations of PEDOT:PSS were used for each electrode, with silver contact pads representing the only metal used in the cell. The active cell material is a non fullerene-bulk heterojunction molecule, and the entire device was encased in waterproof parylene.

The device is described in the paper Fully Inkjet‐Printed, Ultrathin and Conformable Organic Photovoltaics as Power Source Based on Cross‐Linked PEDOT:PSS Electrodes, published in Advanced Materials Technologies. With the 0.1cm² cells weighing in at 0.057 milligrams each, the group also demonstrated that a standard soap bubble was able to support their weight.

The cells were also tested for exposure to seawater and fresh water, and the group says its future work will focus on understanding device behavior in contact with sweat or saliva, for better integration with medical sensor devices. “This work brings organic photovoltaics one‐step closer to their integration in elaborate systems, such as stand‐alone sustainable cutaneous or implanted biomedical devices,” the paper concludes.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.