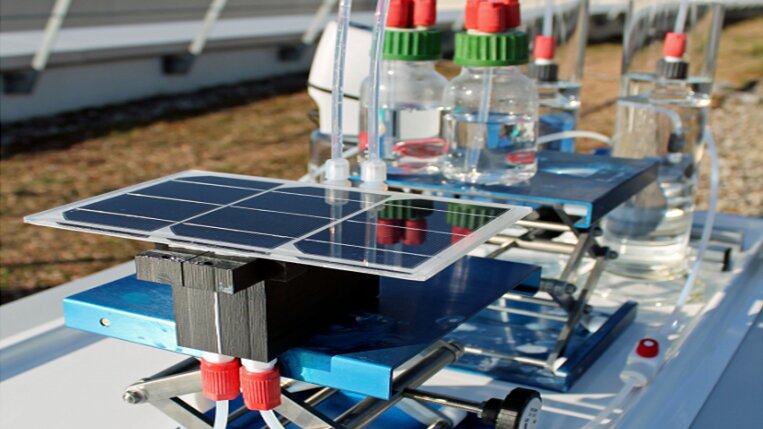

An EU-funded research project coordinated by German research institute Helmholtz-Zentrum Berlin (HZB) has tested several configurations for solar-powered hydrogen generation in order to find the best combination between the PV technology and electrolyzers.

The €2.5 million PECSYS project (Technology demonstration of large-scale photo-electrochemical system for solar hydrogen production) was launched in early 2017 with the goal of developing a prototype on an area of at least 10 square meters that converts more than 6% of the incident solar energy into hydrogen while maintaining stable operation for at least six months.

More than three years later, the results of these efforts have been released. “Initially the plan was to test different materials and then select the best for final implementation in a demonstrator. However, we soon learned that different approaches provide different benefits. Instead of deselecting several options and keeping only one, we therefore decided to investigate a number of technologies,” said the project coordinator, Sonya Calnan.

The research group worked, for example, on a polymer electrolyte membrane PEM stack solution developed by German institute Forschungszentrum Jülich that is said to receive water input only on the cathode side. It tested the solution's long-term outdoor operation in sizes exceeding laboratory scale while avoiding the use of platinum group metals. The applied PV technologies were silicon-based heterojunction solar cells and copper, indium, gallium and (di)selenide (CIGS) devices, and the former was preferred due to its high efficiency, low temperature coefficient, high open circuit voltage and intrinsic bifacial ability. “The move was justified by existing plans to build one or more big manufacturing facilities in Europe,” the researchers said, likely referring to plans by Swiss tech group Meyer Burger to set up a GW-sized heterojunction module production.

A pilot hydrogen facility was set up with full-sized silicon heterojunction modules and CIGS modules connected to polymer electrolyte membrane (PEM) electrolysers. “The installation generated an average of 42.9 g/h of hydrogen with an average solar to hydrogen efficiency of 10% over one month of continuous outdoor operation,” the research team explained.

A second experiment was conducted at the heterojunction solar module factory of Italian utility Enel, which is also a project partner, in Catania, southern Italy. “Bifaciality represents an innovative solution to increase the hydrogen production yield without increasing cost,” Calnan said. “We could demonstrate a solar to hydrogen efficiency of 13.5 % and a hydrogen production rate of 307 mg/h at a solar irradiation level of 1,000 W/m2 and an ambient temperature of 25 °C. This is an increase of 14 % compared to a monofacial operation.”

The project, funded by the Horizon 2020 Research and Innovation program, Hydrogen Europe and N.ERGHY, runs until the end of the year. The Competence Centre Thin Film and Nanotechnology for Photovoltaics Berlin at the HZB led the coordination, bringing together expertise from the Jülich Research Centre (Germany), Uppsala University (Sweden), the National Research Council of Italy as well as from two PV companies: Sweden’s Solibro Research AB and Italy’s 3SUN.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

If we develop gasious hydrogen.. Oxygen separator, things are easy and cheaper… Looks feasible.