Grace Solar has developed a new solar tracker system. The mounting structure supplier said Chinese solar developers have been slow to adopt single-axis trackers because of high upfront costs and fears over the technology’s reliability.

Xiamen Grace Solar Technology Co Ltd says its new Linkage Tracker System product has been wind tunnel tested for dynamic stability by consultancy RWDI. Grace Solar said it adapted its design after the tests to offer a higher damping ratio and to deploy stiffer and larger section posts and middle beams, as well as enabling the product to rely on a higher natural frequency. That combination of the three parameters will prevent the tracker prematurely reaching the ‘instability onset' from where it starts to fall, subject to ‘torsional divergence'. The latter phenomenon, formerly known as torsional galloping or torsional flutter, is the most common – and most feared failure mode – for single-axis trackers. Periodic vortex shedding on the leading and trailing edges of the module span leads to a self-excitation of forces. The modules force themselves to ever steeper angles before shedding another vortex, again and again. The phenomenon traps the structure as wind speeds have to reduce by a significant margin before a tracker can exit torsional divergence. The topic has been extensively discussed in trade media of late and multiple vendors have proposed designs to address the issue.

Grace Solar's product sheet says its tracker will assume a safety position from wind speeds of 18m/s (65kmph), with the time needed to reach the safety position given as eight minutes. The tracker can sustain gusts of three-second duration for wind speeds of up to 45m/s (162 kmph).

Popular content

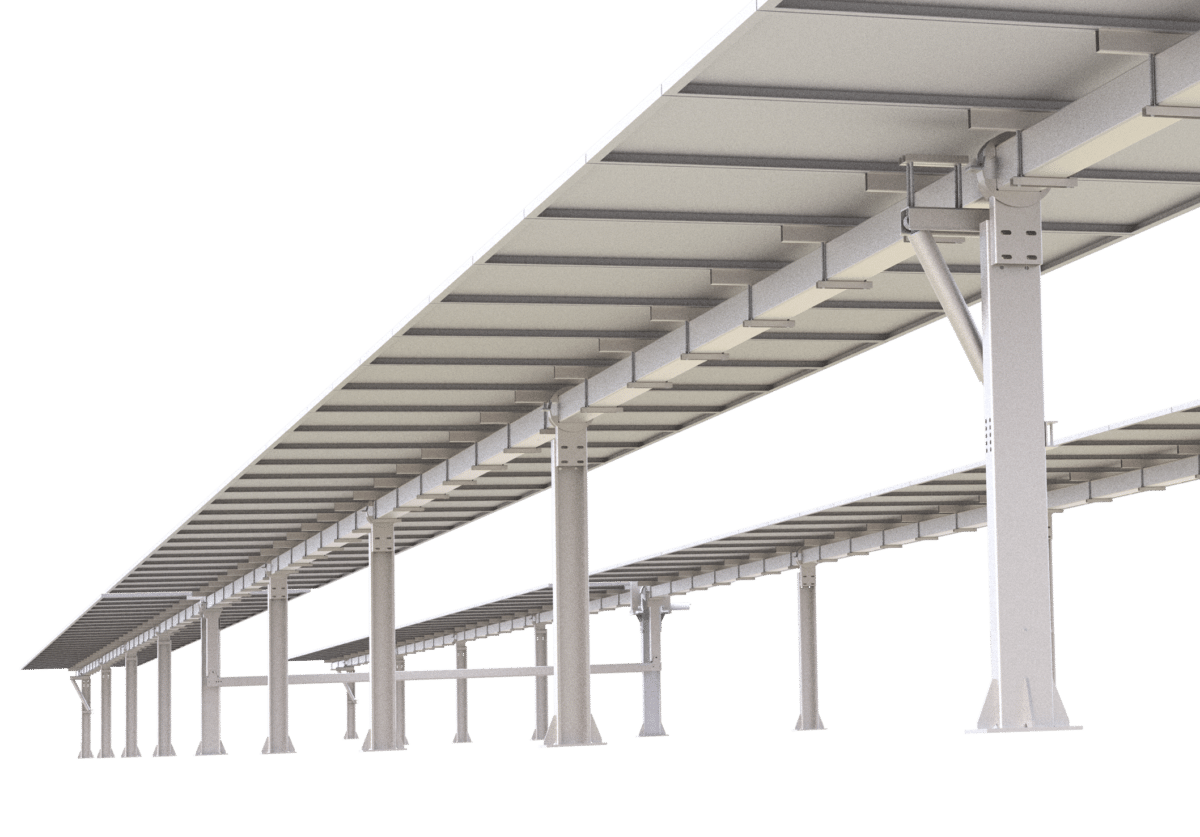

The manufacturer says it has come up with a single-row, two linkage design. Two tracker rows can be connected by a linkage design which halves demand for individual drive motors and requires one engine per tracker. Grace Solar says the tracker can be arranged so 4-6 strings can be installed per motor, reducing cabling and other auxiliary costs. The range of movement is reported as ±60 degrees, with astronomic tracking algorithm offering a mechanical tracking accuracy of ±2 degrees and a claimed control tracking accuracy of less than 2 degrees. The maximum east-west slope gradient the device can cope with is less than 15 degrees, and the maximum north-south slope, less than 5 degrees, according to the company. With reported power consumption of less than 100 Wh per day, the tracker should leave sufficient generation gain for its owners. The mounting scaffolding comprises a mixture of hot-dip galvanized steel components and aluminum-magnesium-zinc plates and profiles, which reportedly optimizes cost and strength.

Grace Solar says the product could be in mass production early in the new year, with an initial annual production target of 2 GW. The company lists the United States, Spain, Australia, Brazil, Mexico, Chile, and Argentina as its first target markets and claims to have already received 300 MW of orders. The manufacturer added, its Linkage Tracking System is compatible with bifacial and larger-form-factor modules.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.