Scientists from Spain's IREC Catalonia Institute for Energy Research and Finland's Aalto University have combined vanadium redox flow batteries (VRFBs) with mini solar modules based on copper, indium, gallium, and selenium (CIGS) tech within a single device, in a bid to take advantage of their high energy density.

The researchers said that the high voltage of the VRFBs presented a challenge for the integration of the PV devices, as the former continuously increase the battery's state-of-charge, while the PV unit must properly match the energy requirements of the storage system.

“The main challenge to be solved for the integrated system is matching the PV maximum power point and the redox flow battery considering the inherent potential shift of the latter,” they said.

They integrated mini panels from American CIGS specialist SoloPower as embedded photo-electrodes with the batteries, without additional power electronics. The CIGS foil was cut into small cells measuring 5.1 cm2 to 5.3 cm2,. The research group used them to make three-cell and four-cell PV modules, which they referred to as “3CM” and “4CM,” respectively. The panels had different open circuit potentials and current densities.

“The final geometric areas of the 3CM and 4CM were 16 and 20.4 cm2,” the researchers said.

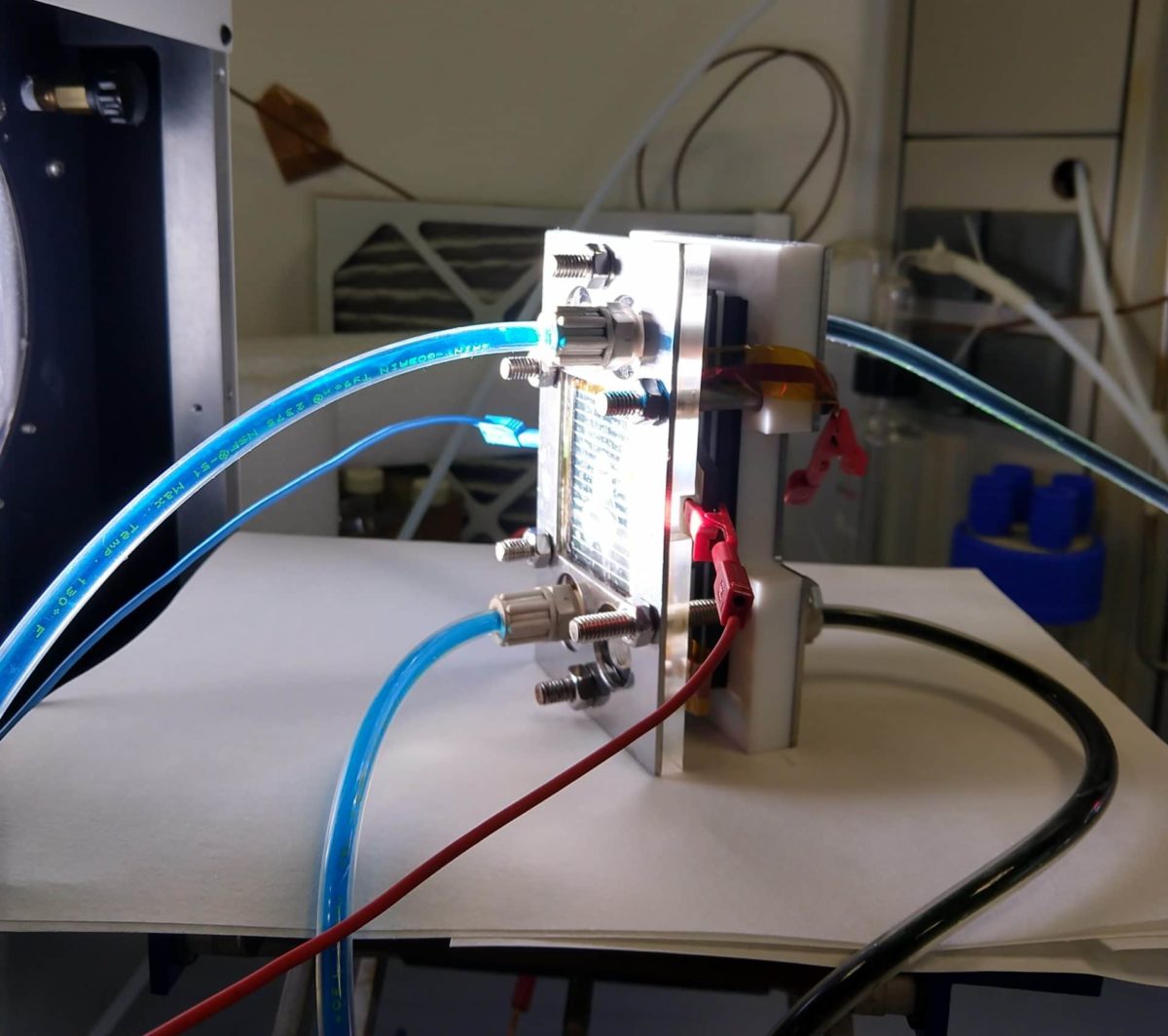

The photo-assisted charge/discharge tests were performed in an adapted electrochemical cell. The CIGS module was integrated by coupling on the negative side of the cell, between the Poly(methyl methacrylate) (PMMA) window and the graphite current collector. A reference electrode was inserted into the negative side of the cell.

The scientists illuminated the panels with a PEC-L01 solar simulator. Both the photocurrent generated by the PV system and the open-circuit potential in the cell were followed with a VMP3 BioLogic potentiostat, which controls the voltage and measures the resulting current.

The academics claimed that the test showed that the CIGS cells had an open-circuit voltage of 0.6 V, a short-circuit current of 35 mA cm2, and an efficiency of 10.3%.

“Alternative interconnection strategies such as monolithic interconnection could probably lead to better solar cell efficiencies than the tabbing method used in the present work,” they explained.

The open-circuit voltage values achieved for the mini panels were high enough, according to the research group, to accomplish the unbiased photocharge in the device. However, the potential variation of the battery cell voltage determined a photocurrent decrease. In the 4CM panel, it reached 21%, but it hit 59% in the 3CM module. This clearly illustrates that “the operation point in this system is not the optimum, so this probably might limit the photocharge of the VRFB,” the researchers said.

The mini module with four series-connected cells achieved full unbiased photocharge under 1 Sun illumination, which resulted in high energy of 77%, a solar to battery charging efficiency of 7.5%, and overall round-trip energy conversion efficiencies of 5.0%. These values, according to the scientists, exceeded all the values reported in the literature for solar VRFBs.

The three-cell module, which was tested under two different battery configurations, exhibited a full dependence on the open-circuit potential of the battery and a lower power performance, due to lower cell voltage.

“We have demonstrated the tremendous potential of this kind of energy storage system by customizing commercial thin-film photovoltaics for the first time, which might shed light on the road for the future development of such solar batteries based on more simple configurations by using already existing technology,” the scientists concluded.

They presented their battery prototype in “Adaptation of Cu(In, Ga)Se2photovoltaics for full unbiased photocharge of integrated solar vanadium redox flow batteries,” which was recently published in Sustainable Energy & Fuels.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.