Scientists from the Tor Vergata University of Rome have fabricated a solar module with cells based on triple-cation cesium methylammonium formamidinium (CsMAFA), which they claim is one of the most stable perovskite materials for PV applications.

The perovskite layer was deposited on a stack made of compact titanium dioxide (C/TiO2) and mesoporous TiO2 (mp-TiO2) in ambient air with a two-step process assisted by air and green anti-solvent quenching. “A manufacturing process must guarantee basic requirements such as low cost, reduced waste, reliability, high throughput, excellent performance and stability of the final product,” the research co-author, Luigi Vesce, told pv magazine. “The procedure is based on a scalable blade-coating process in the air without the need for nitrogen.”

He estimated the cost for manufacturing the module at around €25 per square meter. “There are all the conditions to transfer this technology on a pilot line and then an industrial line,” he further explained. “We are currently using this methodology for several European projects and one of these is aimed at building a photovoltaic plant, which will be a further testbed.”

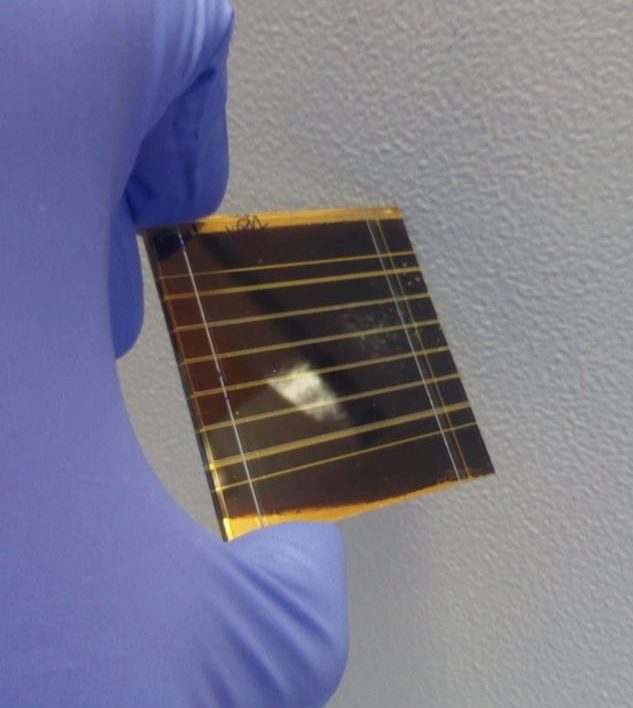

The module is composed of five series-connected cells with each an area of 2.01 cm² and has an aperture area of 11 cm². “We fabricated each module using a semiautomatic blade-coating machine equipped with a heated moving table, a blade coater, a syringe applicator, and a hot-air knife,” the academics specified. “The process is completely confined inside the machine box with controlled temperature and humidity, without any manual operation except for the substrate loading/unloading.”

The best performing device among those produced in the laboratory showed a power conversion efficiency of 16.1%, an open-circuit voltage of 5.59 V, a short-circuit current of 37 mA, and a fill factor of 72.5%. The module efficiency, the researchers went on to say, is not only higher than that of a similar module built through spin-coating, which achieved a 15.5% efficiency, but also only 6% smaller than that of the single small-area cells.

More details on the panel and the related manufacturing process can be found in the paper Ambient Air Blade-Coating Fabrication of Stable Triple-Cation Perovskite Solar Modules by Green Solvent Quenching, published in RRL Solar.

In March, the University of Rome Tor Vergata in Italy also presented a perovskite solar module with a total active area of 42.8 cm2 and aperture area of 50 cm2. The panel was built with 20%-efficient perovskite cells connected in 14 series and was able to retain 90% of the initial efficiency after 800 h of thermal stress at 85

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

“The best performing device among those produced in the laboratory showed a power conversion efficiency of 16.1%, …”

How many devices were made to get the one with 16% efficiency? A histogram of the measurements for all devices would be much more informative.