Researchers at the Dresden University of Technology (TUD) have fabricated a solar cell based on all-inorganic cesium-lead iodide (CsPbI3) perovskite, which is also known as black perovskite.

“Our choice to study the CsPbI3 was motivated by the fact that it shows superior stability as compared to the commonly used organic-inorganic lead halide perovskites,” TUD researcher Yana Vaynzof told pv magazine. “Considering that stability is one of the key challenges preventing perovskite photovoltaics from being widely applied in industrial applications, we chose to focus on the most promising and stable perovskite composition.”

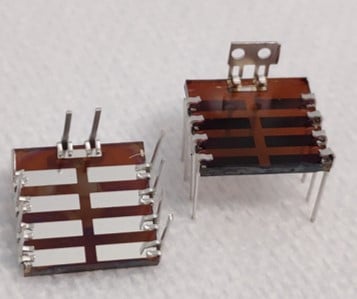

The German group decided to deposit the perovskite layers onto the cell by thermal evaporation, a technique it describes as having many advantages in terms of both economic and environmental aspects. “First of all, thermal evaporation is a well-established fabrication method in industrial settings, suggesting that evaporation of perovskite solar cells can be easily performed using existing facilities in the industry without the need for further investment,” Vaynzof explained. “Secondly, deposition by thermal evaporation is easily scalable — this stands in contrast to the common deposition of perovskite solar cells by solution processing, which is mostly optimized for small area devices only.” Lastly, thermal evaporation is a solvent-free deposition method that has additional benefits in terms of lowering costs and due to the fact that such solvents are toxic to humans and the environment.

Lead(II) iodide (PbI2) and cesium iodide (CsI) were co-evaporated at a low temperature of 100 degrees Celsius with a small amount of phenylethylammonium iodide (PEAI), which is an ammonium salt used to improve stability and optoelectronic quality in perovskite cells. “The PEAI containing thermally evaporated γ-CsPbI3 perovskite films exhibit a far better film microstructure and a preferential crystal orientation,” the scientists stated, noting that this results in a substantial decrease in defect density.

The solar cell showed a power conversion efficiency of 15% and an open-circuit voltage of 1.1 V. “Moreover, this performance surpasses that reported for solution-processed PEAI containing γ-CsPbI3 perovskite solar cells (PSCs) based on the same composition, illustrating that thermally evaporated PSCs can compete and even outperform most PSCs deposited from solution,” the researchers further explained.

The cell was also able to retain around 90% of its initial performance after 215 days of exposure to dim light at room temperature. “The development of efficient and stable thermally evaporated solar cells is of key importance to their future integration into industrial applications,” Vaynzof emphasized. “Due to the low temperature of processing (<100C), these devices can also be deposited on flexible substrates and thus find a broad range of applications for renewable energy generation.”

Popular content

The details on the novel evaporation process can be found in the paper “Efficient Thermally Evaporated γ-CsPbI3 Perovskite Solar Cells,” published in Advanced Energy Materials.

The research on black perovskite has seen increasing interest in recent years. In March, an international research team led by the Soochow University in China developed a 15.1%-efficient flexible quantum dot solar cell based on CsPbI3. The researchers built the cell by integrating quantum dots (QDs) with high surface areas into a thin hybrid interfacial architecture (HIA) and by adding phenyl-C61-butyric acid methyl ester (PCBM), which is one of the best-performing electron acceptors commonly used in organic photovoltaic devices, into the CsPbI3 quantum dot layer.

Another interesting research project was conducted in 2019 to uncover the secrets of black perovskite. According to the study, which involved scientists at 11 research centers on three continents, the interface between perovskite and substrate that is formed during annealing at high temperature remains even after a return to ambient temperature. If the temperature drop is quite steep, perovskite can retain the crystal mesh of the interface and adapt to it.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.